Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Meat package inspections are essential in the food industry, especially for processors and manufacturers looking to comply with federal regulations that ensure consumer safety and product quality. The food labeling process for meat and poultry products is governed by strict guidelines established by both the FDA (Food and Drug Administration) and USDA-FSIS (United States Department of Agriculture Food Safety and Inspection Service). Non-compliance with these regulations can result in severe consequences, including legal penalties, product recalls, injunctions, and even the shutdown of manufacturing operations. Fortunately, meat processors using the Vimaan PackVIEW conduct meat and poultry package inspections quickly and efficiently to ensure their products meet all necessary federal requirements.

Meat Processors need to adhere to the USDA-FSIS and FDA packaging requirements.

The FDA and USDA-FSIS mandate that all labels for meat and poultry products comply with specific guidelines to protect consumers and ensure transparency. These regulations are designed to provide consumers with vital information about the meat products they purchase, including details that can influence their buying decisions and protect their health. Some of the most critical labeling elements required by these regulatory bodies include:

In addition to these labeling requirements, the Federal Meat Inspection Act (FMIA) mandates that all meat products sold commercially undergo stringent inspections. This ensures that the labeling is accurate and in full compliance with federal guidelines. Violations of FMIA or FDA/USDA-FSIS labeling regulations can lead to significant penalties, such as hefty fines, costly product recalls, and in severe cases, manufacturing halts or shutdowns.

With such high stakes, it is critical for meat processors to adopt innovative solutions that can safeguard their operations from errors in labeling and ensure continuous compliance.

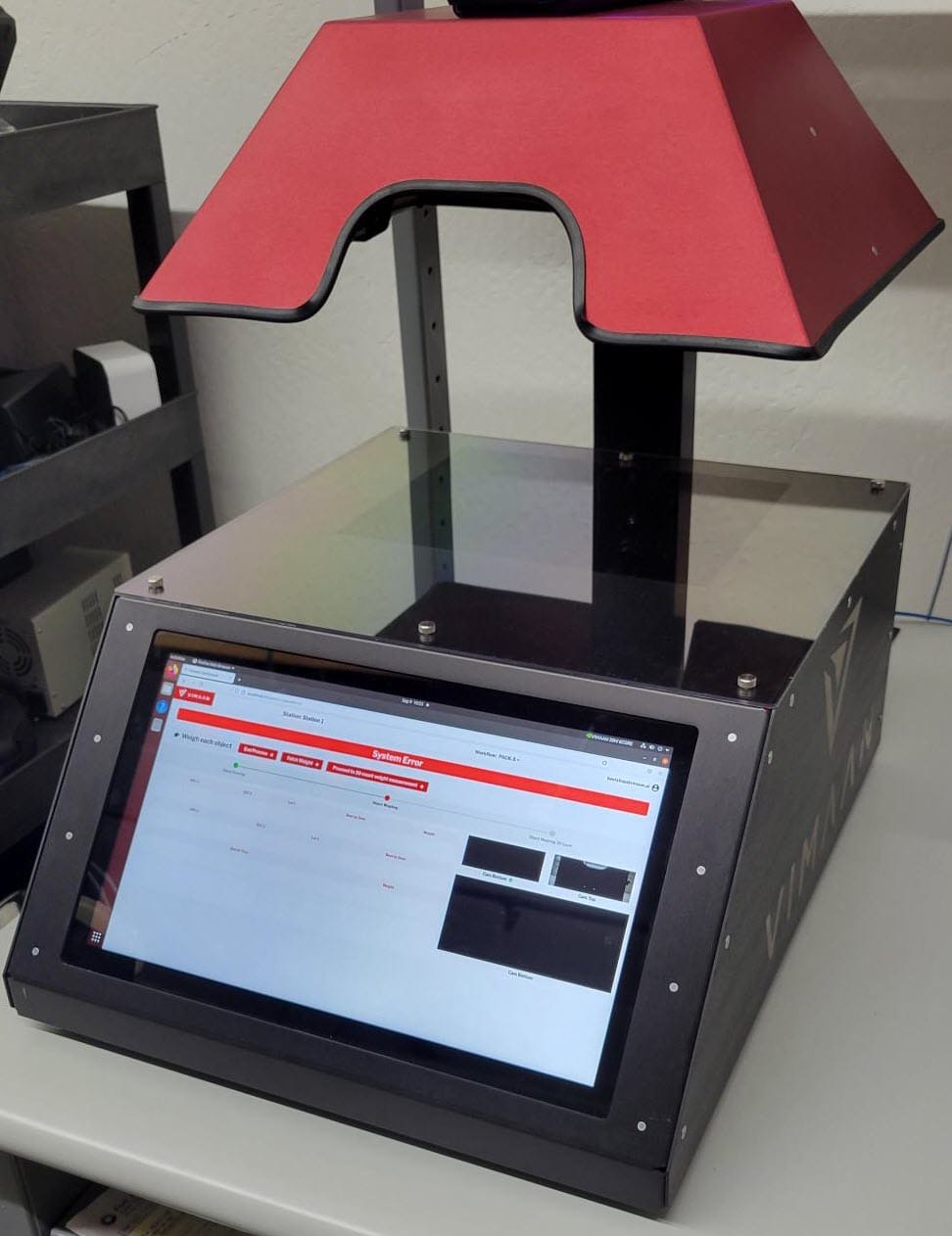

The Vimaan PackVIEW computer vision inspection system enable meat processors adhere to the complex and ever-changing labeling regulations. As a purpose-built meat package computer vision inspection system, PackVIEW uses advanced algorithms to automate the label inspection process, drastically reducing the chances of human error and non-compliance.

Automated Label Verification

Real-Time Error Detection

Regulation Compliance Tracking

Detailed Reporting and Traceability

Scalable for Large Operations

Reduced Human Intervention

With the potential legal ramifications and costs associated with non-compliance, meat processors must prioritize precision and accuracy in their labeling practices. Vimaan’s PackVIEW system provides an effective and efficient solution to meet these challenges, ensuring that your meat and poultry packaging inspections consistently meet the highest standards set by the FDA and USDA-FSIS.

By leveraging advanced computer vision technology, PackVIEW helps meat processors avoid costly mistakes, maintain compliance with ever-evolving regulations, and safeguard their brand’s reputation. Adopting this solution not only protects your business from legal and financial risks but also enhances operational efficiency, allowing you to focus on delivering high-quality, safe products to consumers.

Investing in PackVIEW means investing in the future of your business—where accuracy, compliance, and consumer safety are assured with every package.

Learn more about meat and poultry package inspection solutions at Vimaan