Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

One of the most important KPIs to any warehouse is high inventory accuracy, and cycle counting is the most effective process for achieving this goal. This process is so critical that 3PLs are contractually obligated to conduct warehouse cycle counting at agreed upon intervals. However, for most warehouses, cycle counting comes with a high cost including excessive amounts of man-hours, picking and put-away delays, and even the risk of employee injury during high bay cycle counting. Warehouse storage has become more vertical, and goods can be stored over 30’ off the ground. Auditing inventory this high is both dangerous and unnerving for designated employees. The risks associated with high bay cycle counting contributes to incomplete and inaccurate inventory reporting.

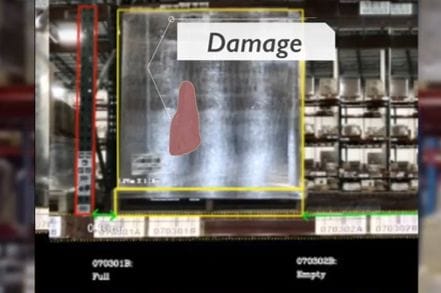

Warehouse cycle counting is a critical and extremely time-consuming process and also required shutting down aisles or complete areas of warehouses, interfering with picking and put-away events. Even with regimented cycle counting, warehouses and 3PLs still achieve sub-par inventory accuracy levels. In 2018, Vimaan was the first company to introduce warehouse drones to conduct automated cycle counting in the warehouse for full production environments. Over the next several years, Vimaan revolutionized the notion of automated inventory cycle counting by capturing full images of goods on shelves and providing information that goes far beyond warehouse barcode reading. Vimaan’s cycle counting solution includes full, high resolution, image “reconstruction” of the face of the shelf, including barcode reading, label text reading, item dimensioning, empty bin reporting, damage detection, discrepancy reporting against the WMS, and location and inventory search features. Vimaan is live with its solution at multiple Fortune 500 facilities, including some of the top 3PLs. In the process, Vimaan has also dramatically reduced the need for associates to perform cycle counting tasks.

From 2017-2022, Vimaan exclusively used warehouse drones to capture inventory information from shelves that can be as high as 35’, and we have flown more missions and conducted more inventory location scans using drones than any other solution provider. But while there is unquestionable value in the data generated by sensors and cameras mounted on these drones and our approach to warehouse cycle counting, Vimaan has also gained significant insights into the shortcomings of using drones to conduct cycle counting in the warehouse, including:

To maintain the richness, comprehensiveness and other advantages of Vimaan’s cycle counting approach, and to eliminate the downsides of using drones to accomplish this goal, Vimaan has engineered StorTRACK, an even more affordable, safer, and faster solution than any other product on the market.

The move to Vimaan computer vision has addressed the warehouse cycle counting pains for several leading global 3PLs. As opposed to enlisting dedicated associates to conduct manual inventory audits, StorTRACK solutions allow for more proactive auditing and reporting of inventory status. Maneuvered by pre-existing warehouse MHE, StorTRACK captures inventory status as high as the MHE can reach. 3PLs and warehouses operating StorTRACK have reported faster and much more accurate cycle count results. The improved efficiencies and accuracies achieved with StorTRACK have allowed these customers to reduce cycle count associated labor by up to 75%.

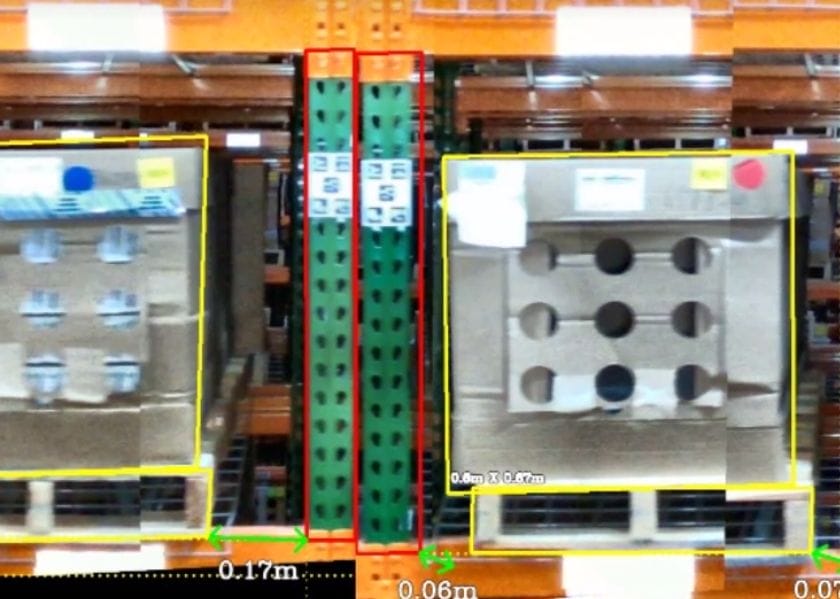

StorTRACK is an industrial-strength sled equipped with an array of computer vision sensors that is handled and maneuvered by pre-existing material handling equipment, including forklifts and order pickers. Warehouse mapping for StorTRACK is only required at the ground level, greatly reducing set-up time and allowing the cycle count solution to be up and running in under a week. Capturing inventory from the floor to the ceiling, StorTRACK processes data with 100% accuracy and up to 10X faster than traditional methods (and 5X faster than a drone). StorTRACK safely functions alongside pick and put activities performed in congested warehouses. Additional benefits include:

• More flexible, robust, and powerful hardware (no weight or aerodynamic design constraints)

•With a battery life that is 24X greater than the drone – StorTRACK substantially improves the cycle count coverage per mission.

• Inventory can be captured “on demand” – for audits and spot checks. Even for warehouse with a single cycle count resource, StorTRACK delivers the fastest ROI.

Easy to use, the warehouse associates simply pick up the StorTRACK with an MHE, start on their pre-defined location (as instructed by an intuitive and easy to use UI), and then follow instructions to complete the cycle count. As StorTRACK is carried down an aisle, lights illuminate the stored inventory and the computer vision powered camera suite reads warehouse barcodes, reads label text, conducts case stow cycle counting, inspects for damages, improves warehouse utilization, cycle counts very narrow aisles, and even identifies inventory in the wrong location. Additionally, StorTRACK reports on open bays to help warehouses maximize the use of all available storage space. No other warehouse cycle counting solution reports on inventory status as quickly or as accurately as StorTRACK.

No barcode scanning, no picking, getting out of the cab, etc. required. Just drive to the specified locations and raise and lower the lift on the MHE. Once completed, the warehouse associate returns and plugs the sled into the charger and the system auto charges and gets ready for the next task.

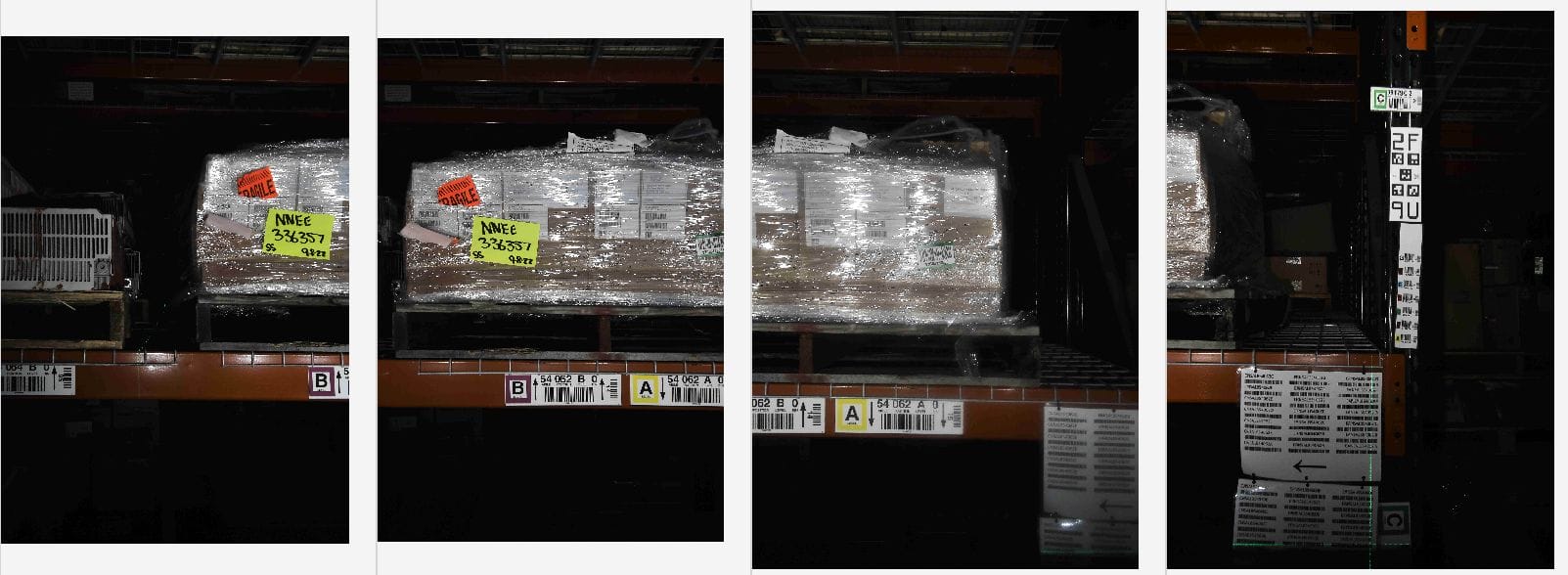

Contents of the entire storage bay are captured by StorTRACK including pallet labels, barcodes, label text, shelve locations and even reads through shrink wrap.

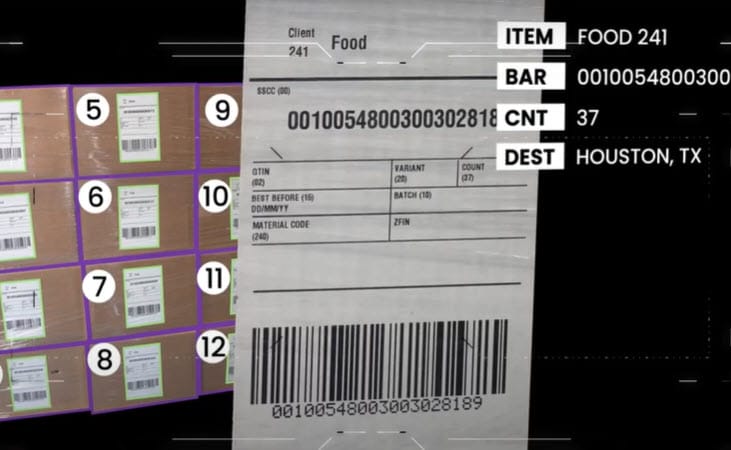

Other automated cycle count solutions only scan barcodes, while Vimaan reads the entire label:

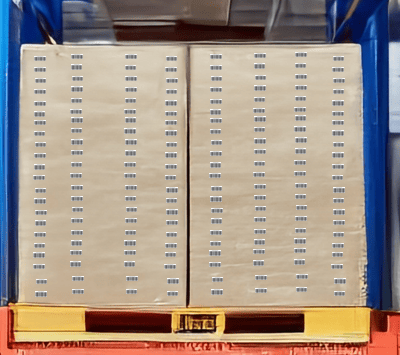

Effective automated cycle count requires the ability to scan more than a single pallet label, StorTRACK features allow for complete capture of pallet contents in one pass:

Designed in the shape of a pallet, StorTRACK operates in the narrowest of aisle environments. Equipped with 4 cameras and embedded LED lighting, StorTRACK cycle counts the entire contents of a pallet in just one pass, even for high density storage. It does not matter how many items are stored on a shelf, StorTRACK will scan 50 items as fast it scans one! Challenges with VNA warehouse cycle counting is no longer a challenge for warehouses that use StorTRACK.

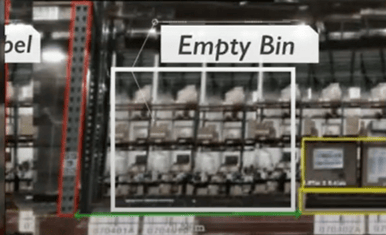

Beyond label reading, Vimaan identifies opportunities to maximize available storage space.

Systematic recording of the number and location of cases stored within a warehouse.

Reconciles the inventory truth from the warehouse floor and shelves with WMS:

Environmental Reporting

All images captured by Vimaan computer vision sensors are automatically stored in photo archives for future and ongoing analysis. Vimaan combines these images together providing 360 views of shelves, pallets and packages for easy access and analysis. Learn more about inventory image stitching.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping