Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Warehouses that employ high-density storage strategies are designed to maximize warehouse utilization space while efficiently storing a large volume of goods or materials. These warehouses are characterized by their utilization of specialized storage systems and technologies that enable them to achieve higher storage capacities compared to traditional warehouses. While many warehouses store pallets on their rack shelves, high density warehouses will store individual boxes, cartons and eaches across their bins. Each one of these standalone containers is identified and labeled as individual goods requiring warehouses to utilize high-density storage scanning and barcode reading to track and cycle count each item.

Today, warehouses store cases of items using many different types of storage strategies. Most common are single SKU pallet storage and case storage location. Cycle counting the case storage locations is particularly labor intensive as it requires each individual case to be scanned. Warehouses that hold high number of SKUs and fewer quantities store in case locations rather than pallet locations. Industries from clothing- apparel, shoes, cosmetics to electronics, furniture may find themselves storing this way, including B2B and eCommerce providers where the item size is bigger than a 8-10 inch.

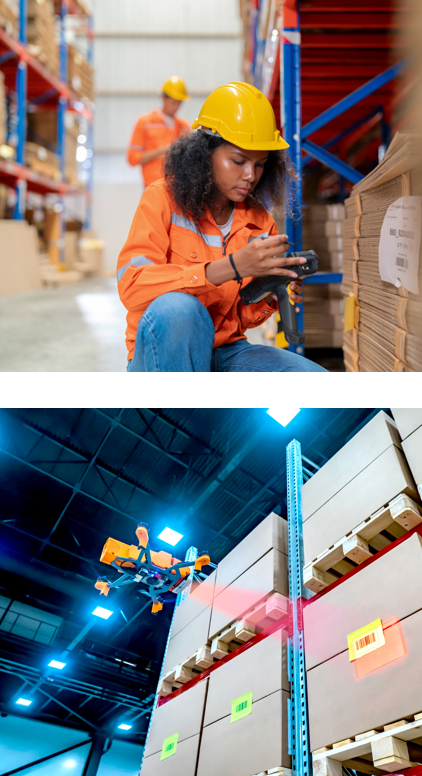

Warehouses need high density scanning solutions that are versatile enough to capture pallets with a single label all the way to a pallet containing 100 separate labeled cases that all need to be scanned.

Keeping track of items in high-density storage warehouses presents multiple challenges due to the complex nature of the storage systems and large volume of inventory involved. With dense storage configurations it is difficult to visually inspect and count each item reliably. This leads to discrepancies in inventory accuracy and challenges in locating specific items when needed, contributing to order fulfillment delays, and increased operational costs. This is why effective high-density storage scanning solutions are critical to these types of operations.

The strategies used to cycle count high-density warehouse shelves will vary from facility to facility. Many warehouses still employ manual counters that visually count standalone items, typically these items lack visible labels and barcodes. For items that do feature visible barcodes, warehouse associates will walk the aisles and lifted by order pickers to scan these individual items. This is a time consuming and error prone approach to high density item scanning, especially when it comes to case stow cycle counting.

Several factors are driving the adoption of cycle count automation in warehouses. High attrition rates and shrinking labor pools are forcing warehouses to supplement labor with cycle count automation, but the results of these technologies are quite varied:

Warehouses utilizing the Vimaan StorTRACK are discovering that many of the issues associated with cycle counting high density items are challenges of the past. Several features of this computer vision system are purpose-built to support inventory scanning of all types.

Designed in the shape of a pallet, any existing forklift or order picker can pick up and maneuver the StorTrack cycle counting system. The wide field of view and embedded LED lighting ensures that densely packed items are captured as fast as the MHE can lift and lower its forks – StorTRACK can scan 100+ densely packed items as fast as it can scan a single pallet. Equipped with an 8-hour battery pack, StorTRACK can scan individual pallets and high-density items for an entire warehouse shift without a single re-charge.

High density storage scanning is no longer an unsurmountable challenge. Computer vison and machine learning technologies have advanced to the point where these goods are reliably captured and reported on as reliably as any other inventory scanning solution. No matter the number of items stored in high density shelves StorTRACK scans and reports on this inventory, even for very narrow aisle (VNA) cycle counting. Designed for speed and reliability, this inventory scanning system can capture a 300’ long x 30’ high warehouse shelf in 35 minutes, regardless of whether the bins contain individual pallets or include densely stored inventory.

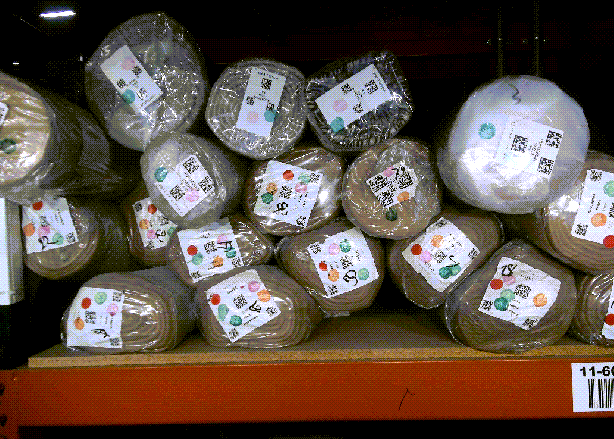

Tracking 10,000’s of rugs was a major challenge for Jaipur Living, a leading luxury rug manufacturer based out of Acworth, Georgia. Densley stored rugs with mixed symmetry and various qualities of labels made cycle counting a time consuming and labor intenstive task. Learn how the manufacturer was able to achieve a 40X improvement in cycle count efficiencies, while doubling their inventory accuracy. Read the Jaipur Living Case Study

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!