Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Efficiently tracking and validating warehouse inventory is at the core of operations and the ability to conduct complete label capture has become a competitive advantage for leading warehouses. While warehouse barcode reading is still a primary procedure for identifying goods, other label content is still used to verify incoming, outgoing and stored goods. Vimaan computer vision solutions are specifically designed to support this level of versatility which allow warehouses to process inventory more reliably and with less labor.

One of the most significant innovations has been the deployment of warehouse computer vision systems capable of complete label capture automation, these systems cover a wide array of labels, including those on stored inventory, LPNS ON incoming and outgoing pallets, individual cases on pallets, and even individual parcels.

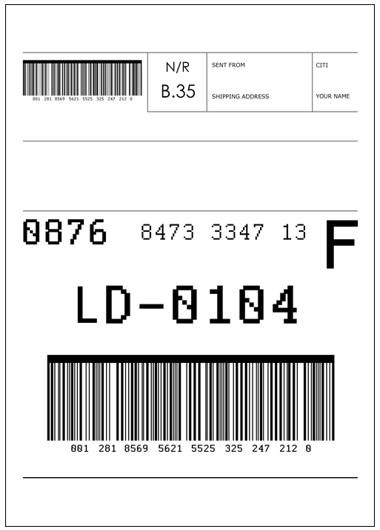

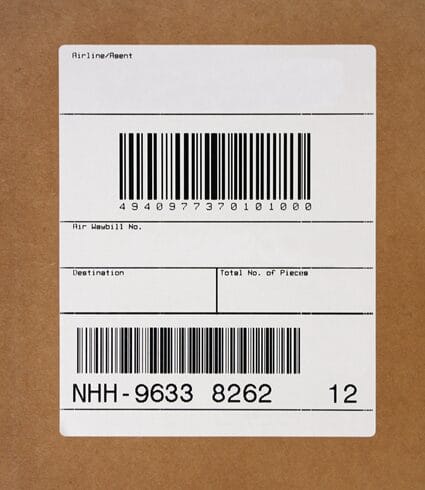

Complete label capture involves the scanning of multiple types of data presented on warehouse labels, which can include everything from reading warehouse barcodes to alphanumeric strings such as SKUs, dates, addresses, and other unique identifiers like images, handling alerts and logos. The ability to automatically capture this information not only streamlines operations but also ensures higher accuracy, reduces human error, and improves overall efficiency in the warehouse.

Previously tracking and inspecting label information beyond the barcode required manual intervention. Workers would read and document requisite alphanumeric data to record labeled goods. This includes visually inspecting a variety of essential information, including product identifiers, batch numbers, shipping addresses, dates, lot numbers, and tracking information. This data is critical for inventory management, shipping accuracy, and maintaining a seamless flow of goods through the warehouse. The expense of manual labor to conduct these activities resulted in only a subset of inventory would be validated. contributing to inventory accuracy issues.

With automated label capture, however, warehouses can routinely scan and process this label data in real-time using Vimaan warehouse computer vision. This capability significantly enhances operational efficiency and accuracy. The system captures labels on:

In order to optimize warehouse operations, complete label capture must be capable of reading a variety of information from labels including:

The combination of these data elements helps ensure the accuracy and efficiency of warehouse operations, from inventory tracking to final delivery.

While the concept of complete label capture may seem straightforward, the execution can be complex. Not all systems are equipped to handle the variety of labels and data formats present in modern warehouse environments. That’s where Vimaan steps in as a leader in the field of computer vision powered label capture.

Vimaan leverages machine learning enabled sensors to read and interpret labels quickly and accurately. Unlike traditional barcode scanners, which may struggle with damaged or poorly printed labels, Vimaan systems use proprietary algorithms to detect and capture predetermined data from a variety of label types.

Systems like StorTRACK, PalletSCAN 360 and ParcelSCAN from Vimaan are engineered to automate some of the most common and labor-intensive activities in the warehouse including:

In modern warehouse operations, complete label capture is an essential tool for improving inventory accuracy and efficiency. By automatically scanning and capturing a wide variety of label data, warehouses can streamline processes from receiving to shipping, ensuring that all products are tracked and processed correctly.

With Vimaan’s computer vision systems, warehouses gain a powerful solution that not only captures label data but also automatically checks for discrepancies, ensuring the highest level of accuracy. Vimaan’s technology integrates seamlessly with existing systems, making it the best choice for warehouses looking to improve their operations and stay ahead in an increasingly competitive marketplace.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!