Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Photographic images captured by Vimaan computer vision sensors are all automatically uploaded and stored in inventory archives for ongoing and future analysis. However individual photo frames only display what appears in a cameras field of view. Warehouse managers have told us that they would benefit from more contextual imagery that displays other goods found on a shared or nearby shelf (or even on shared pallets). To support quick and efficient analysis, Vimaan combines inventory images together providing 360-degree views of shelves, pallets and packages. All of these stitched inventory images are easily searched and displayed in the Vimaan inventory visualization web application, ViewDECK.

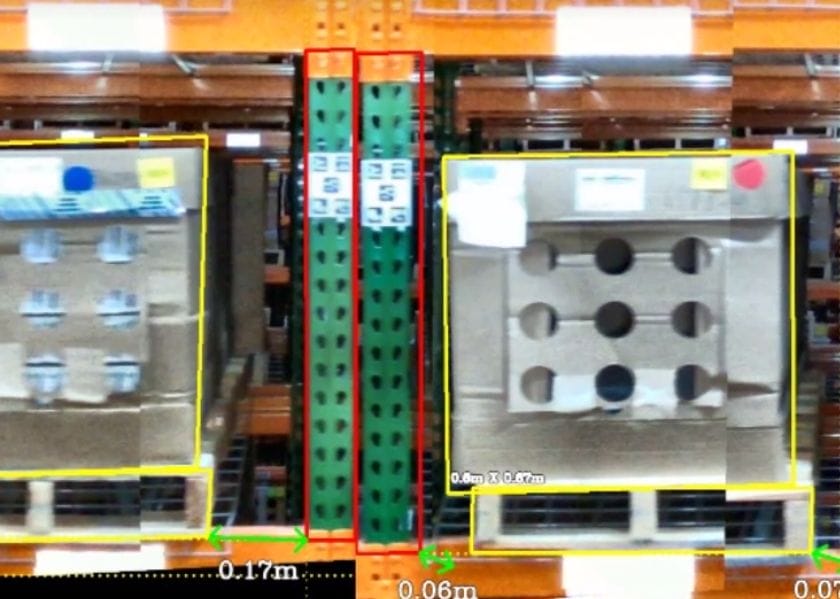

Accessing these stitched inventory images in ViewDECK, Vimaan customers gain an environmental insight of neighboring assets, much like a Google “street view” of their warehouse. Users can easily zoom, pan and scroll through stitched images to spot and resolve inventory and storage utilization issues. When discrepancies and anomalies are quickly resolved it supports a higher degree of inventory accuracy and control over their stored goods.

Inventory image stitching is available with all Vimaan computer vision solutions, including StorTRACK and DockTRACK. Vimaan customers typically use StorTRACK as as means of inspecting high bay storage shelves. StorTRACK scans shelves and reports on a variety of performance KPIs such as empty bins, mis-located inventory, damaged products or pallets, and even goods with missing labels. Stitching these images together provides customers with a complete view of the storage environment, saving them unnecessary trips into the shelves. Additionally, multiple images captured by StorTRACK can be stitched together to offer a complete view of a specific set of inventories (like the boxes to the left). Inventory image stitching and solutions like StorTRACK save warehouses enormous amounts of time, improves inventory trackability, reduces labor requirements and contributes to the development of a true warehouse digital win. These sorts of savings have allowed Vimaan customers to achieve ROI in months and not years (compared to other warehouse automation technologies.

All VIMAAN solutions transmit scanned inventory data to the ViewDECK web application for near real-time analysis. ViewDECK is an intuitive tool that allows you to easily search. All ViewDECK data is automatically transmitted to your WMS; ensuring you have the most up to date view of your inventory. Learn more about inventory visualization with ViewDECK.

Inventory accuracy is a challenge in almost every warehouse we walk into, and the reasons behind the inaccuracies vary. Understanding the truth behind your inventory involves not just cycle counting of stored goods, but also gaining a complete view through the use of image stitching which provides a more compressive view of your inventory.

Automated cycle counting for dense inventory and pallets. Scans a 300′ aisle in 35 minutes.

Incoming and outgoing goods are easily scanned and validated with Vimaan computer vision.

Fast four-sided pallet scanning validates, counts and inspects cases in near real time.