Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Warehouses and distribution centers employ several common methods to choose from when conducting pallet pick missions. Processes will change dependent on resource availability, size of orders, inventory locations and contents of orders. The most common methodologies include:

While pick to order missions are widely used, they are also the most susceptible to item fulfillment failures; and this therefore leading 3PLs and Fortune 500 companies have embraced computer vision to improve pallet order picking efficiencies.

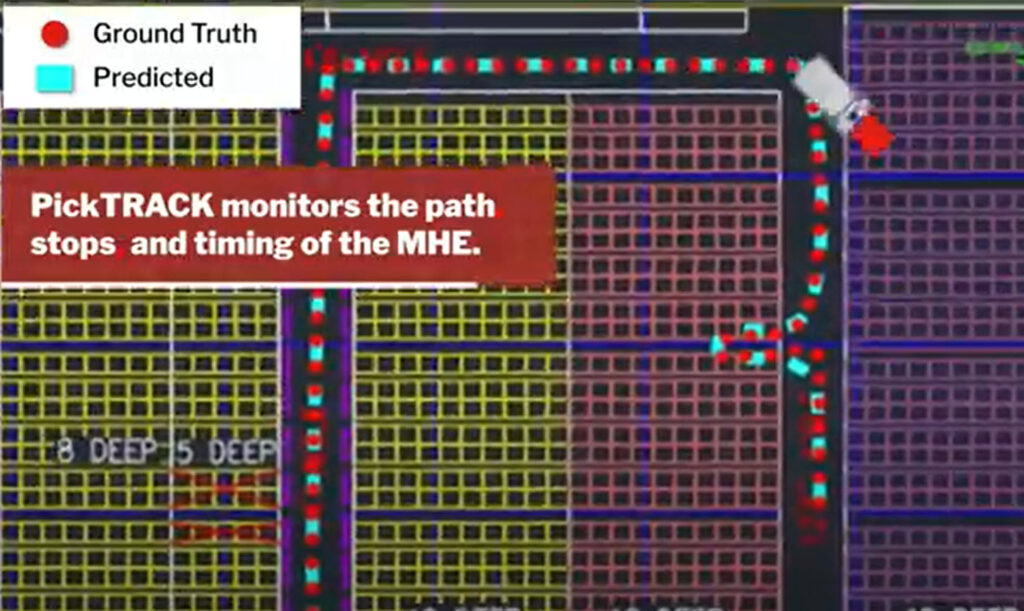

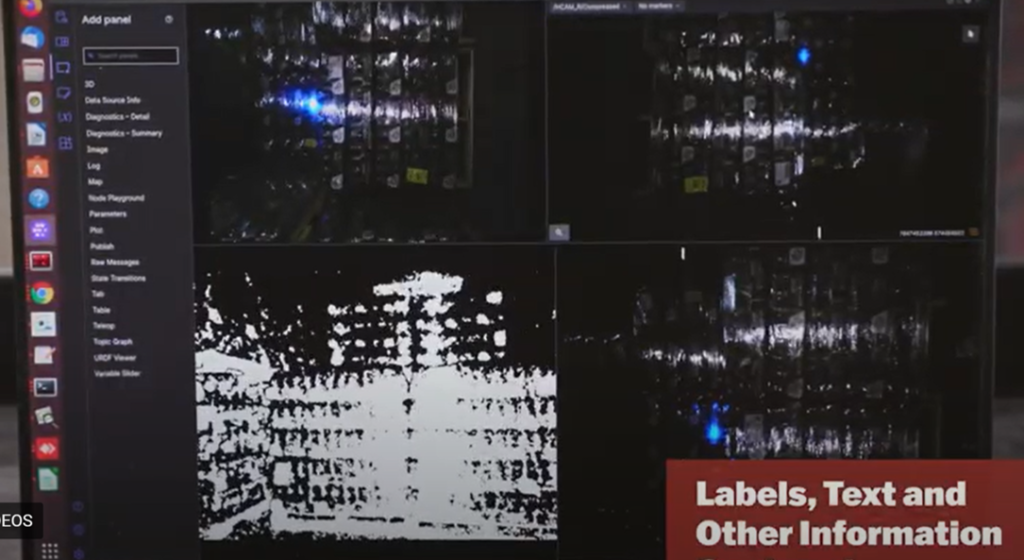

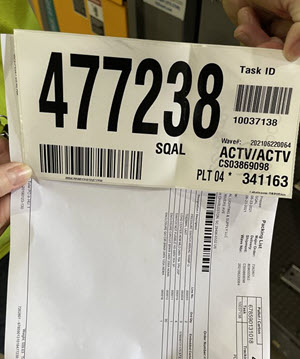

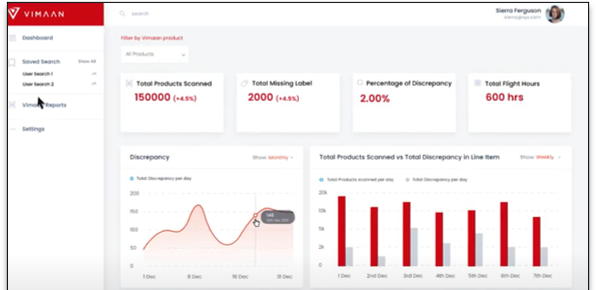

Vimaan solutions help ensure that warehouses maintain high inventory accuracies and know exactly where to find stored goods. As pickers embark on pallet picking missions, Vimaan put-away and cycle counting data ensures they spend more time picking and less time searching. PickTRACK sensors, mounted on MHE, capture label and location data as pallets are picked, Vimaan alerts warehouses when orders are wrong and/or incomplete before the picking mission is complete, ensuring that the right pallets and bulked items are collected for fast and efficient order fulfillment.

Pallet and Bulked Item Pick Verification Implementation

Vimaan helps keep tabs on your inventory the moment it enters your warehouse to the second it leaves. DockTRACK sensors capture incoming inventory and validate both SKUs and quantities against the WMS (or other system of record). Once the intake process is complete, MHEs equipped with PickTRACK carry the inventory to its designated storage location; this put-away activity is reported to the WMS. PickTRACK also tracks stored pallets as they are moved from one area of the warehouse to another thus, supporting future pallet picking missions. By tracking the picks, puts and movements of pallets within, and in and out of the warehouse, Vimaan essentially provides a near real time tracking of pallet locations in the warehouse. All of these processes help lay the groundwork for successful pallet order picking.

Pick Path Optimization

Automated Computer Vision

Pallet Pick List Validation

All VIMAAN solutions transmit scanned inventory data to the ViewDECK web application for near real-time analysis. ViewDECK is an intuitive tool that allows you to easily search. All ViewDECK data is automatically transmitted to your WMS; ensuring you have the most up to date view of your inventory. Learn more about inventory visualization with ViewDECK.

Inventory accuracy is a challenge in almost every warehouse we walk into, and the reasons behind the inaccuracies vary. Understanding the truth behind your inventory involves not just cycle counting of stored inventory but also accurate tracking of inventory movement and reconciling it in near real time against your WMS.

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping

Material Handling Equipment integrated, precise real-time put away inventory location tracking.

Scans, tracks and INSPECTS high volume packages entering and leaving the warehouse.

Web-based application provides inventory status across the warehouse in near real-time.