Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Safe, Efficient and Cost-Effective Cycle Counting is essential to maintaining very high inventory location and count accuracy. Vimaan engineers have spent years in warehouses across North America to better understand persistent challenges involved with cycle counting and managing inventory. A WMS is fundamental to managing and tracking goods, but a WMS is only as good as the data it receives from the warehouse floor and shelves. This is why Vimaan has designed the next generation of StorTRACK, engineered to perfect the practice of automated cycle counting in the warehouse.

StorTRACK includes a mobile camera and sensor frame engineered to improve the speed and quality of warehouse cycle counting. It conducts fast scans of warehouse racking to enable high frequency cycle counting. Lifted and maneuvered by pre-existing MHE, StorTRACK enables warehouses to scan inventory shelves from the floor to the highest level and every shelf in-between.

Cycle count missions begin with an inventory manager requesting inventory audit tasks through StorTRACK’s Task Manager, a tablet application. Tasks are uploaded to the StorTRACK Operator UI instructing MHE Operators of their cycle counting mission. The Operator picks up and drives StorTRACK through the appropriate aisles and scans designated rack locations. StorTRACK provides real-time feedback to the operator to ensure scans accurately capture the target zone in one pass.

After StorTRACK has captured the appropriate rack locations, it is returned to the base station and uploads data to the server. Vimaan uses computer vision and machine learning algorithms to analyze the uploaded images and extract the relevant data (such as the item label, location, dimensions or other information). Vimaan’s inventory database portal, ViewDECK, is then updated with the new output and reports any discrepancies. Watch a technical overview of StorTRACK.

While other solution providers deliver (not so) autonomous airborne barcode scanners, Vimaan has instead focused on delivering a more complete inventory management platform that delivers the warehouse ‘truth’ to a customer’s WMS. This truth includes proactive alerts for discrepancies against the WMS, the validation of quantities, high density inventory scanning, expiration dates, and part numbers. StorTRACK also provides an archive of searchable images of inventory locations, flagging of quality deficiencies, misplaced goods, and open storage space.

StorTRACK delivers the most comprehensive capabilities of any automated cycle count solutions:

| 1D/2D Warehouse Barcode Reading | Label Text Reading |

| High Bay Inventory Scanning | Container Dimensioning |

| Improved Bin Utilization | Case Stow Counting |

| Identify Missing or Damaged Labels | High Density Scanning |

| Very Narrow Aisle Scanning | Warehouse Utilization Improvements |

| Damage Detection | Environmental Reporting |

One of the promises of warehouse drones is that they are independent and autonomous and do not need human intervention to conduct their missions. But the reality is that most warehouses have loose material – such as shrink-wrap, packaging tape, corrugate or paper – on the shelves or the floor. If left unattended, these items can get sucked into a drone’s rotors and pose a risk to both humans and inventory assets. So most “autonomous” drone missions are preceded by humans that need to clear the aisle, thus negating the value of true autonomy. Learn more about the differences between warehouse drones and StorTRACK.

StorTRACK includes several computer vision enabled cameras and integrated lighting that ensures even the most densely packed inventory are accurately scanned and read. This includes capturing label information on pallets, cases and eaches, providing the most comprehensive cycle count automation available.

StorTRACK digitally recreates the entire aisle view using computer vision techniques like image stitching. Additionally, StorTRACK provides added value by detecting damages, dimensioning cases, reporting on bin occupancy levels, counting boxes on a pallet and verifying individual label attributes (such as expiration date, addresses, etc.).

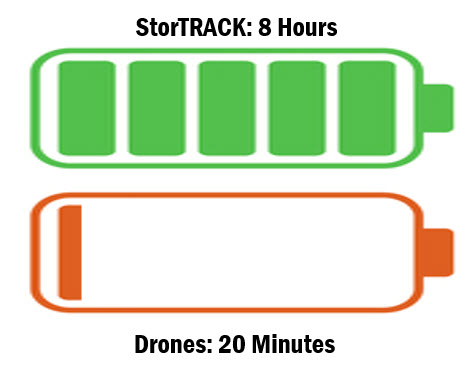

The StorTRACK unit’s battery lasts for 8 hours, which is 24X longer than a typical drone! This allows the cycle counting MHE operator to operate continuously from aisle to aisle for long periods of time, thus increasing labor efficiency.

The larger field of view and the increased battery life enable large sections of the warehouse to be cycle counted in a single mission. StorTRACK can scan one face of a 30 feet tall and 300 feet long aisle in an hour or less. In fact, some of our customers are using StorTRACK to conduct year end audits of the entire warehouse over a single weekend with a single StorTRACK unit!

StorTRACK is a highly cost-effective solution, even after accounting for the labor required to conduct the cycle count. Even a warehouse with as few as two people conducting cycle counting can generate an ROI and annual savings with StorTRACK, and in addition, realize all the benefits of extremely high inventory accuracy, visibility and traceability. StorTRACK digitally recreates the entire aisle view using computer vision techniques like image stitching. Additionally, StorTRACK provides added value by detecting damages, dimensioning cases, reporting on bin occupancy levels, counting boxes on a pallet and verifying individual label attributes (such as expiration date, addresses, etc). Learn more about StorTRACK cycle counting scanning capabilities here.

StorTRACK scans warehouse shelves from the floor to the highest level and every shelf in-between, delivering highly accurate inventory status to the WMS. Unlike other inventory capturing technologies that only scan barcodes, StorTRACK reads all label attributes including:

Manual auditing can be replaced

with the faster and more exact

cycle counting of the StorTRACK.

Along with scanning shelves to ensure

accurate goods placement, StorTRACK also

provides reports on empty storage spaces.

StorTRACK has access to

your manifest and can quickly audit

goods with +99% accuracy.

Outdated and slow hand-held

scanners are easily replaced with

the fast and reliable StorTRACK.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!