Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

In the fast-changing landscape of modern logistics and manufacturing, warehouse efficiency and accuracy are essential to any operation. To meet the demands of today’s supply chains, businesses are turning to leading edge technologies, like robotics and machine learning based computer vision. It’s impossible to miss the overwhelming options in robotics when it comes to material handling in the warehouse. In the context of warehousing, computer vision and machine learning are revolutionizing traditional operations, reducing labor costs, enhancing productivity, and paving the way for a new era of streamlined logistics management.

Machine Learning based Computer Vision (CVML) is an interdisciplinary field that enables systems to interpret and understand visual information from the world around them. CVML leverages a combination of hardware and software to replicate human vision, processing images and videos to extract meaningful insights. This technology has found its way into various domains, including healthcare, automotive, food and beverages and most notably in the past few years in warehousing.

In the context of warehousing, CVML is a game-changer. Traditionally, warehouses have been driven by manual labor, hand scanners and even paper-based systems, leading to inefficiencies, errors, and excessive operational costs. However, with CVML, many of these challenges are mitigated. By equipping warehouse workflow with cameras, sensors, and advanced algorithms, businesses gain real-time visibility into their operations.

Vimaan has developed this primer to provide both warehouse novices and veterans alike with an in-depth understanding of how warehouse computer vision works and benefits warehouses and distribution centers of all sizes. At a high-level, warehouse CVML supports these critical inventory management disciplines:

Object Detection and Tracking with Warehouse CVML

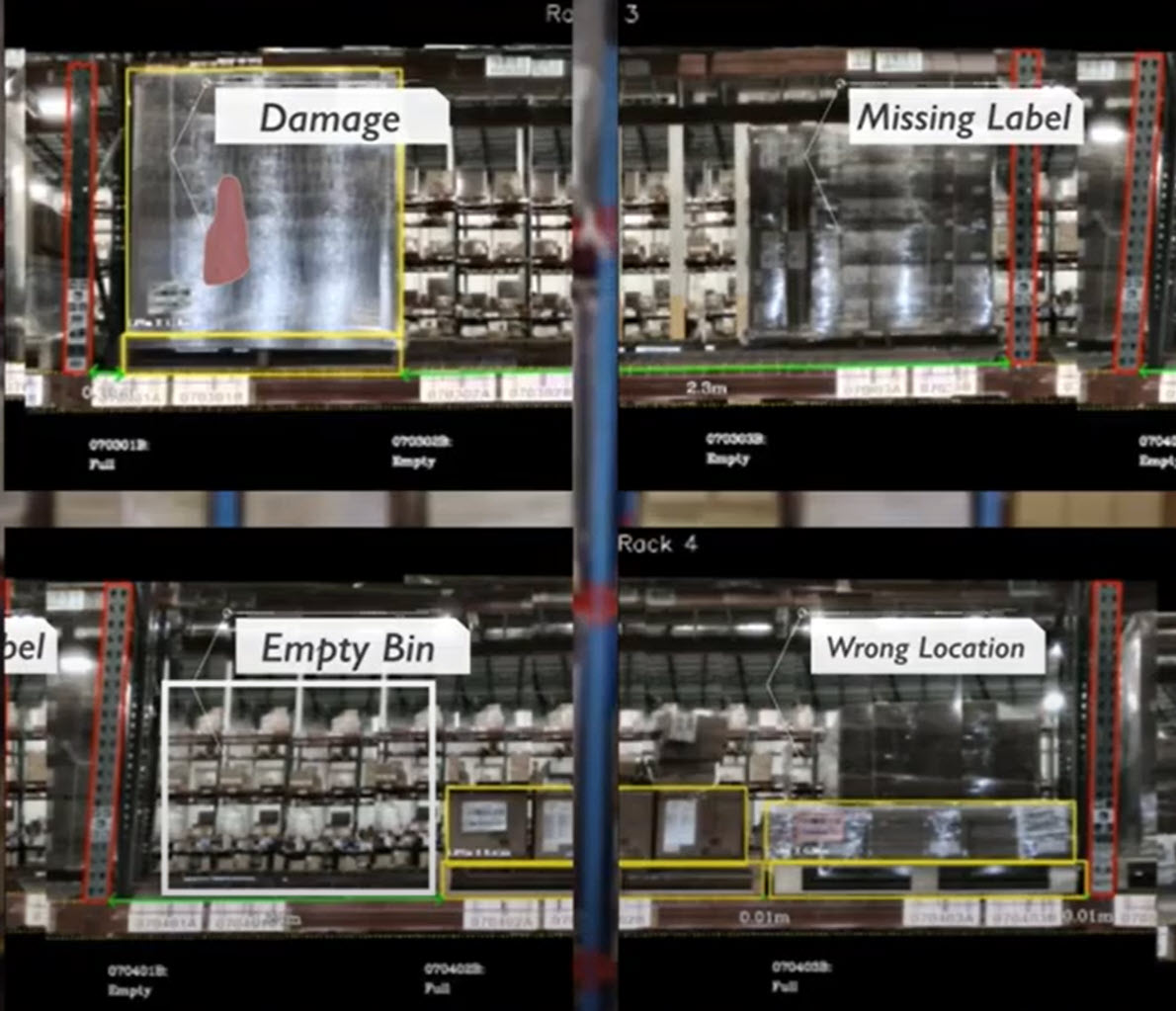

Warehouse CVML Enhances Quality Control and Defect Detections

Warehouse CVML Provides Data Driven Insights

One of the key applications of computer vision in warehouses is object detection and tracking. Computer vision systems identify and locate objects within the warehouse. This capability is particularly valuable for inventory management, as it enables automatic tracking of stock levels and precise location information. With computer vision, businesses reduce the time spent searching for items, hand scanning high density storage areas, minimize stockouts, and optimize storage space.

Ensuring product quality is a critical aspect of warehousing, especially when dealing with sensitive goods or those subject to regulations. Warehouse computer vision technology can be employed to inspect products for defects, anomalies, or damages as they move through the supply chain. By analyzing visual data, the system can quickly identify deviations from the norm and trigger alerts, enabling prompt corrective actions and preventing substandard products from reaching customers.

To maintain the richness, comprehensiveness and other advantages of Vimaan’s cycle counting approach, and to eliminate the downsides of using drones to accomplish this goal, Vimaan has engineered StorTRACK, an even more affordable, safer, and faster solution than any other product on the market.

The adoption of warehouse computer vision generates a wealth of data that can be harnessed for further operational improvements. For example data collected by Vimaan computer vision solutions like StorTRACK provide actionable insights for the warehouse WMS and the Vimaan web application, ViewDECK. By analyzing patterns, trends, and historical data, warehouses can make informed decisions, optimize bin utilization, and reduce the labor previously required to manually collect and analyze inventory data. This data-driven approach leads to increased warehouse efficiency, reduced operational costs, and better overall customer service and satisfaction.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping