Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

5-sided pallet scanning empowers warehouses to scan and register incoming and outgoing inventory more efficiently. Typically, warehouse associates are still being asked to use handheld readers to scan barcodes on package labels (no matter where the labels may appear). Associates circle the pallets taking aim at one of the 5 sides to capture codes; and as any warehouse worker will tell you, these handguns are less than reliable and often experience latency issues which further slows the process of pallet receiving. Additionally, warehouse associates are often required to manually enter additional inventory data that is not available in the barcode, which introduces additional challenges such as data entry inaccuracies and processing delays.

Vimaan sensors and computer vision quickly and efficiently scan all 5 sides of pallets

up to 5X faster than traditional manual methods, with much more reliable results!

Place and scan solutions have recently been introduced by barcode reading companies, but the process of positioning, placing and removing the pallet from the scan area can be extremely slow and labor intensive. These barcode reading solutions still require associates to inspect for damages, photograph all sides of the pallet and enter additional label information not found in barcodes.

Motivated by the challenges faced by industry’s leading supply chain companies and 3PLs, Vimaan has engineered a first-of-its-kind novel solution that addresses the 5-sided scan challenges experienced by busy warehouses and distribution centers.

5-Sided Pallet Scanning Implementation

This novel solution automates the warehouse receiving and shipping 5-sided pallet scanning process using a combination of sensors, cameras and proprietary computer vision and machine learning technology. The solution is comprised of two primary components:

How 5-Sided Pallet Scanning Works

During the automated inbound and outbound pallet scanning process, the system automatically detects when a driver is about to pick up a pallet. The front face of the pallet is scanned automatically, and as the driver starts to drive through the “gate”, the sensors automatically detect the presence of the pallet and then proceeds to scan the entire pallet in 3D as well as each of the 4 visible faces. Vimaan’s proprietary computer vision and machine learning backend software collates all the data collected from all sensors and cameras to extract label information, dimensions, damage, and other anomalies.

Placed in inbound and outbound stations, DockTRACK Pallet is an industrial strength pallet scanning gate powered with Vimaan proprietary computer vision sensors and artificial intelligence. Like scan tunnels and legacy scanning technology, DockTRACK Pallet successfully reads barcodes from all visible sides of a pallet (even at extreme angles). Beyond barcodes, DockTRACK Pallet addresses the challenges that other solutions do not, such as:

Finally, the challenge of scanning labels on the hidden vehicle facing side of the pallet is addressed with PickTRACK sensors that are easily attached to the front of forklifts and other MHE. Like all other Vimaan computer vision solutions, PickTRACK sensors are automatically triggered as labels come into their field of view and capture all required label information including 1D/2D barcodes, logos and human readable text. The MHE carries the pallet through the DockTRACK gate referenced above, allowing for all 5 sides of the pallet to be successfully read. By deploying Vimaan 5-sided pallet scanning, warehouses can improve their pallet scanning copy and paste from above ONE pallet every 2-3 minutes to THREE pallets every minute!

Along with improving the processing speeds of inbound and outbound pallets, the Vimaan 5-sided pallet scanning solution also provides added benefits to our customer’s warehouses including:

5-Sided Pallet Scanning Capabilities

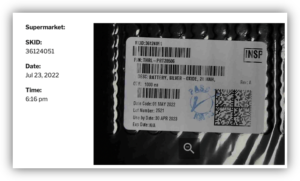

Label Scanning and Identification

Multi Case Label Reading and Associationn

Pallet Dimensioning

This enables significant cost savings through lower labor requirements, while making the process of pallet receiving faster with higher quality results. Using Vimaan’s solutions, process times can improve from ONE pallet every THREE minutes (or longer) to THREE pallets (or more) every minute! This includes the automation of 5-sided pallet scanning, 1D/2D barcode reading, label text reading, damage detection, dimensioning, WMS (Warehouse Management System) validation, and image capture and archiving. See the applications below on more details on how Vimaan improves the process of inbound pallet receiving.

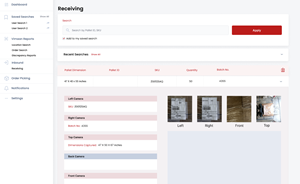

All VIMAAN solutions transmit scanned inventory data to the ViewDECK web application for near real-time analysis. ViewDECK is an intuitive tool that allows you to easily search. All ViewDECK data is automatically transmitted to your WMS; ensuring you have the most up to date view of your inventory. Learn more about inventory visualization with ViewDECK.

See firsthand how this diverse set of pallet scanning systems solve the most common and time intensive warehouse challenges including: