Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

In the realm of modern warehousing, the integration of advanced technologies is redefining how operations are conducted, optimizing efficiency, accuracy, and overall performance. Central to this transformation is warehouse computer vision, a sophisticated technological approach that harnesses the power of artificial intelligence and machine learning to interpret visual data and facilitate automation in various tasks.

At its core, warehouse computer vision involves enabling systems to capture, interpret and understand visual information from the environment, much like human vision. This is achieved through a combination of hardware, software, and algorithms designed to process and analyze images and videos.

Computer vision systems in warehouses rely on cameras, sensors, and other imaging devices to capture visual data from the warehouse environment. These devices are strategically placed throughout the facility to cover critical areas and gather relevant information. The data acquired from these devices serve as the input for subsequent processing. For example, Vimaan offers specific computer vision enabled devices in key areas of the warehouse including receiving/shipping bays, cycle counting storage racks and packaging stations.

Object detection is a crucial aspect of warehouse computer vision. Advanced algorithms, such as convolutional neural networks (CNNs), are employed to detect and recognize objects within the captured images. These algorithms are trained on vast datasets to learn patterns and features that correspond to specific objects, enabling them to accurately identify objects in real-time. For instance, on a warehouse conveyor that is transporting packages, DockTRACK Parcel detects and identifies these objects as they are moved from one area of the warehouse to another.

Inventory feature extraction is a fundamental step in warehouse computer vision where relevant characteristics of the visual data associated with inventory are identified and isolated. This process transforms raw pixel data into meaningful features that algorithms can analyze. For example, Vimaan customers will work with field engineers to identify specific inventory attributes that they need captured and analyzed. This often includes the isolation of key attributes found on inventory labels such as barcodes, dates, address, lot numbers and more. Vimaan engineers then train cameras and sensors to isolate, capture and record this data and then associate it with the appropriate warehouse workflow.

Once objects are detected, localization involves determining the precise geo-location of these objects within the warehouse facility. This information is crucial for tasks like inventory management, order picking and item verification. Additionally, object tracking algorithms can be employed to follow the movement of objects over time, ensuring a continuous understanding of their whereabouts within the warehouse. Warehouses employing Vimaan can more easily track inventory location, boosting overall inventory accuracy and improving downstream processes like order picking and outbound shipping.

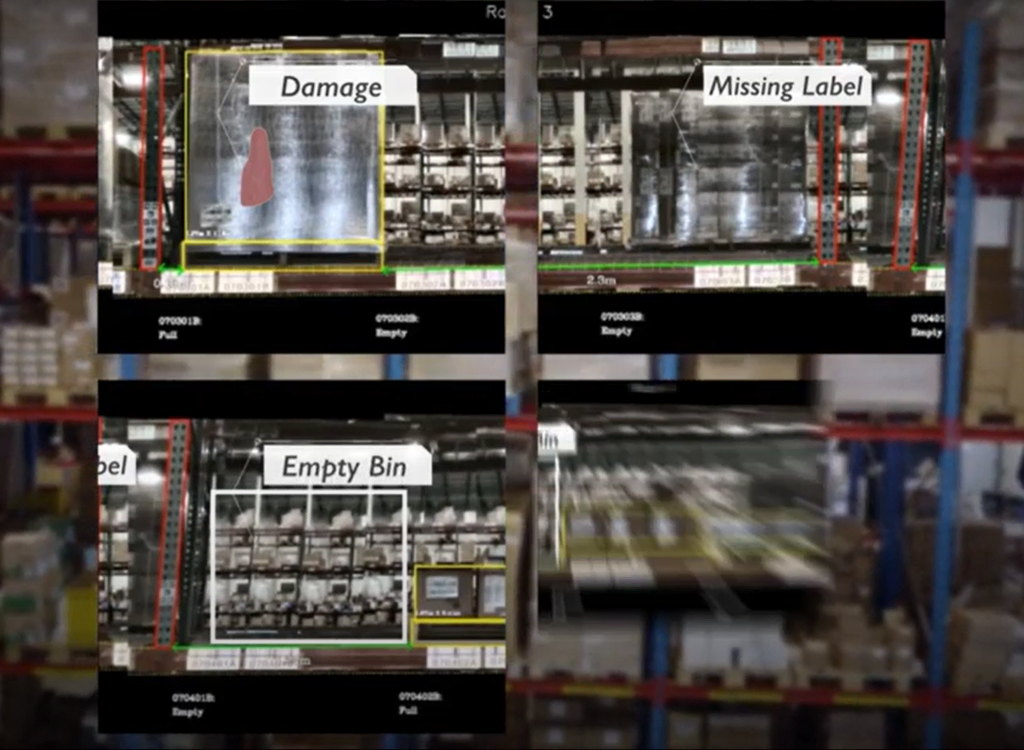

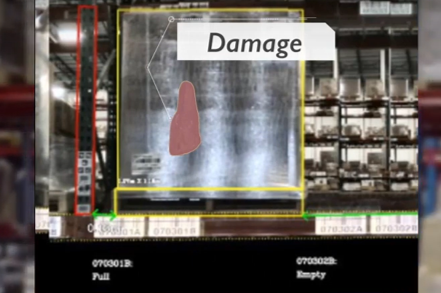

The processing of visual data is carried out in real-time or near-real-time, depending on the specific application. As images are captured and analyzed, the system generates insights that are fed into the Warehouse Management System (WMS) software. These insights drive automated decision-making processes, such as inventory updates, bin utilization, quality control alerts, and routing instructions. Cycle counting data captured by the Vimaan StorTRACK allows warehouse managers to easily understand and analyze the inventory differentials of what the CVML models provide, and what is recorded within the WMS. Additionally, order packers receive instant verification and feedback during order assembly activities. PackVIEW from Vimaan validates item SKUs and quantities prior to being placed in outgoing orders. This helps ensure all orders are 100% complete before being shipped to customers.

Older forms of inventory management including scan guns and RFID (radio frequency identification) do not provide satisfactory evidence that inventory was accurately documented. Laser scan guns misfire and often lose contact with warehouse wifi. The laser scans may verify a code was captured, but there is no guarantee the item is located where it is supposed to be. There is no way to visually confirm the location of a scanned item without physically traveling to the shelf location and visually confirming yourself.

While some warehouses swear by RFID, it comes with an extensive array of challenges that have limited adoption of the technology. Like laser scanning, RFID does not offer the visual proof that an item or container is physically where it is being reported to be, and like laser scanning, the only way to positively confirm the location of an item is by physically traveling to the shelf. However, with computer vision, personnel have access to a warehouse digital twin that allows staff to confirm the status of inventory location from their WMS in addition to the ViewDECK web application for Vimaan customers.

The lack of visual proof is a big drawback to laser scanning and RFID technology, and this is why warehouse dock workers are often asked to photograph incoming and outgoing pallets to capture their conditions before being processed. Alternatively, warehouse computer vision from Vimaan digitally captures inventory photographs and even stiches images together to provide a record of visual proof of inventory conditions. This level of visual documentation helps warehouses prove the condition of a pallet or package before being shipped or the completeness of orders before they were shipped to customers.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping