Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Warehouse automation has helped improve the outbound shipping process for parcels. Most modern 3PLs and warehouses have embraced the use of near real-time tracking to keep tabs on outgoing packages. For large volumes of parcel shipping, “scan tunnels” are used to detect and scan barcodes on four, five, or even all six sides of a parcel. However, these tunnels cannot successfully deliver the higher quality, more comprehensive, and automation needed to fully optimize the outbound parcel shipping that 3PLs and warehouses need in order to truly make their outbound parcel processes as efficient as possible.

Scan tunnels use complex hardware technologies including adjustable mirrors, scanners and machine vision cameras to capture and detect barcodes. But they are generally limited in their ability to perform other functions such as reading text on a label, detecting multiple labels, capturing damage on a parcel, etc. Another drawback is that because of their “unidimensional” ability to read only barcodes, if the barcode is damaged or not visible, the parcel cannot be read, and has to be re-routed to a “hospital” lane where manual intervention becomes necessary. In facilities where millions of parcels are processed every day, this can become a huge expense in added labor and also cause delays in processing. Additionally, scan tunnels are expensive and take years to achieve an ROI.

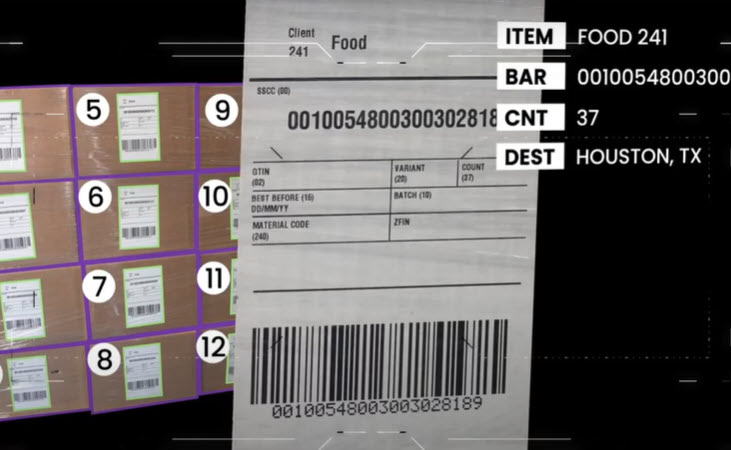

While more traditional processes use labor and “scan tunnels” to scan barcodes for parcel shipping workflows, Vimaan captures the ENTIRE PARCEL in 3D, and extracts all label data including barcodes, human readable text, box dimensions, and even inspects for damage, discoloring and other package anomalies. ParcelSCAN validates outbound inventory against the warehouse system of record, WMS, ASN, or shipping slip, and identifies discrepancies – providing near real-time alerts. Like all other Vimaan solutions, ParcelSCAN populates a searchable photographic image archive of all shipments to enable analytics and reduce claims and associated charges.

Automated Outbound Parcel Shipping Implementation

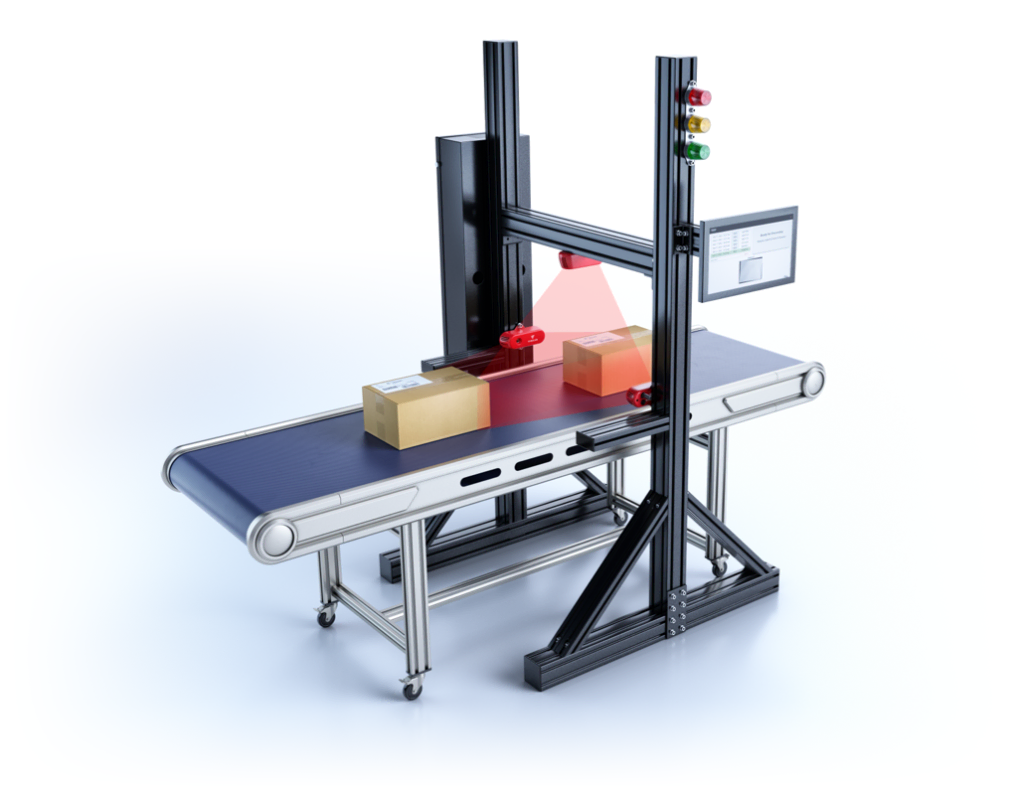

Vimaan automates the outbound parcel shipping process using a combination of sensors, cameras and proprietary computer vision and machine learning technology. The sensors and cameras are mounted around the conveyor belt, much like a scan tunnel, but smaller in footprint.

How Automated Outbound Parcel Shipping Works

During the parcel process shipping on a conveyor line, ParcelSCAN automatically detects when a package is coming down the conveyor. The entire parcel is scanned automatically. All the faces of the parcel are captured in 3D. Vimaan’s proprietary computer vision and machine learning engine collates all the data collected from the sensors and cameras to extract label information, dimensions, damage, or other anomalies.

5-Sided Parcel Shipping

Damage and Anomaly Detection

Parcel and Package Dimensioning

Other automated package and parcel outbound scanning systems only scan barcodes, while Vimaan reads the entire label:

Featured Outbound Parcel Shipping Process

Damage detection with Vimaan computer vision occurs during all major material handling stages including induction, put-away, packaging and shipping, our algorithms are designed to identify any anomalies and alert warehouse workers in real-time.

Inventory accuracy is a challenge in almost every warehouse we walk into, and the reasons behind the inaccuracies vary. Understanding the truth behind your inventory involves not just cycle counting of stored inventory, but also accurate tracking of inventory movement starting with inbound pallet receiving to outbound shipping all while reconciling it in near real time against your WMS.

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping

Inbound palleted goods are scanned, tracked and inspected faster with greater accuracy.

Combined with PalletSCAN, MHE equipped with PickTRACK provides automates inbound pallet receiving.

Scans, Tracks and INSPECTS High Volume Packages during inbound receiving and outbound shipping.