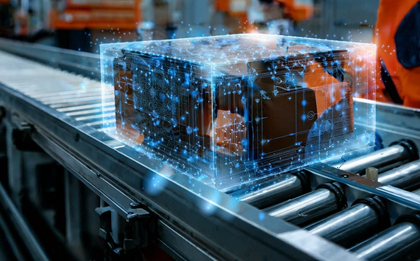

Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

Relying solely on labor to ensure accurate warehouse receiving is a challenge for most 3PLs, DCs and Brands. Vimaan solutions include a powerful combination of warehouse computer vision and sensors that automate the inventory scanning, inspection, dimensioning and tracking of all incoming pallets and packages. This enables our customers to reduce costs and reliance on manual labor; while receiving more reliable and higher quality data. Vimaan supports faster and more precise inventory data capture, and even provides archived photographic evidence of condition and quantities of inventory entering the warehouse.

Establishing inventory tracking and accuracy starts with improved warehouse receiving of pallets and packages.

Lowers labor requirements and make the process of pallet warehouse receiving faster with higher quality results. Using Vimaan solutions warehouses can improve from receiving ONE pallet every 3 minutes to up to 3 pallets per ONE minute

Automates, streamlines and digitizes the shipping label scanning process, increases label “read rate” during warehouse barcode reading, reduces labor requirements, and the time between physical receipt of parcels and the WMS “system” receipt of parcels.

Through advanced algorithms and image processing techniques, computer vision can accurately measure pallet dimensions with high precision, even in dynamic environments.

In addition to scanning package labels, the Vimaan ParcelSCAN system uses advanced laser technology to dimension both large and small containers, delivering precise volume measurements.

Vimaan computer vision delivers an unprecedented level of damage detection and inspection, allowing AI warehouses to lower their costs and increase inventory quality.

Ti-Hi Counting allows warehouse to count pallet contents and size. This typically manual task optimizes the warehouse pallet receiving process and speeds up delivery time. Learn how this can be improved with automation.

See firsthand how this diverse set of pallet scanning systems solve the most common and time intensive warehouse challenges including:

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping

Automated Pallet Receiving with Ti-Hi, Case Counting, and SKU Verification

Scans, tracks and INSPECTS high volume packages and parcels entering and leaving the warehouse.

Web-based application provides near real-time insights and actionable inventory tracking data.