Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

San Jose, CA (December 11, 2024)

VIMAAN, a pioneer in computer vision solutions for warehouses, today announced the integration of advanced laser dimensioning technology into its ParcelSCAN system, further enhancing its capabilities in automated package processing and inspection.

Building on ParcelSCAN’s core functionalities like barcode scanning, quantity tracking, SKU validation, label text reading, and damage detection, the new package dimensioning capability provides precise volume measurements using advanced laser technology. This enhancement maintains ParcelSCAN’s signature high-speed processing, ensuring efficient package processing operations.

“This enhancement to ParcelSCAN demonstrates our ongoing commitment to solving real warehouse challenges through innovative technology,” said Chahal Neema, Head of Product at VIMAAN. “By adding high-precision dimensioning to ParcelSCAN’s existing capabilities, we’re helping warehouse operators optimize available storage space, plan shipping loads better, select the most appropriate carriers and of course reduce expensive labor dependencies.”

The enhanced ParcelSCAN system now provides:

The new feature optimizes shipping and receiving processes while maintaining the accuracy rates over 99.8% that Vimaan customers have come to expect.

The dimensioning technology maintains ParcelSCAN’s modular design approach, allowing for easy incorporation into existing workflows and mounting options for both conveyors and tabletops. “This enhancement particularly addresses the challenges faced by distribution and fulfillment centers dealing with high-volume package processing, where accurate dimensional data is critical for optimal shipping operations” added Neema.

Vimaan’s latest rich data set, accessible through their ViewDECK reporting portal, can also be seamlessly delivered to a customer’s Warehouse Management System (WMS) or other systems of record. This new package dimensioning capability complements Vimaan’s earlier launch of drive-through pallet dimensioning with PalletSCAN 3D, a solution deployed in some of the world’s busiest distribution centers.

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

San Jose, CA (September 11, 2024)

Vimaan, the leading provider of AI-enabled computer vision solutions for warehouse inventory tracking and visibility, today announced that it has once again been recognized by Gartner®.

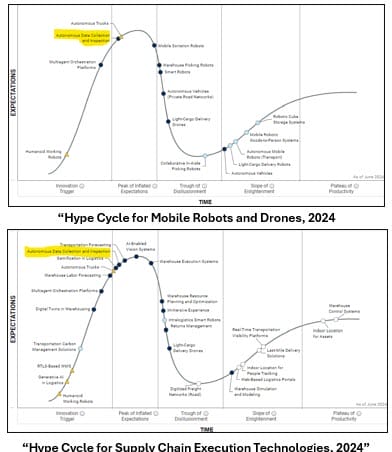

This year Vimaan has been recognized in two different Gartner Hype Cycle Reports. The first inclusion is part of the “Hype Cycle for Mobile Robots and Drones, 2024”, the category Vimaan has been included in is “Autonomous Data Collection and Inspection”. The other inclusion is in the “Hype Cycle for Supply Chain Execution Technologies, 2024” and Vimaan is listed under the same data collection and inspection category.

“Vimaan AI-enabled computer vison solutions automate the data collection process across several key workflows in the warehouse,” stated Chahal Neema, Head of Product for Vimaan. “For example, StorTRACK captures and analyzes stored inventory data and automatically compares against the warehouse WMS.” StorTRACK was introduced to the market in 2023 and provides fast and highly accurate cycle counting for warehouses of all sizes.

Vimaan was also recognized last year as a Cool Vendor in the 2023 Gartner Cool Vendors in Logistics Technology. This 2023 report states that “logistics organizations remain under pressure to control costs while dealing with unprecedented labor challenges. Supply chain technology and logistics leaders seeking to use emerging technologies to help improve performance given these constraints should explore the vendors in this research.”

In addition to StorTRACK, the PalletSCAN family of solutions have been enabling customer warehouses to further bolster their autonomous data collection since being launched at Modex earlier this year. “Our customers are seeing great improvements in productivity since deploying PalletSCAN in their warehouses. For example, PalletSCAN 3D has been deployed at some of the busiest distribution centers in the country and are dimensioning thousands of pallets a day at each location. Additionally, a major retailer has been using PalletSCAN 150 to automatically conduct Ti-Hi pallet counting, this solution counts and confirms case quantities in seconds saving both time and the number of resources needed to process pallets,” added Neema. “Both of these pallet scanning solutions are drive through enabled, meaning MHE operators can literally drive through our pallet scanning gateways to collect data in seconds.”

Gartner Attribution & Disclaimer

Gartner, Hype Cycle for Mobile Robots and Drones, 2024, By Dwight Klappich, Abdil Tunca, Federica Stufano, Simon Tunstall, 25 June 2024. Gartner, Hype Cycle for Supply Chain Execution Technologies, 2024, By Dwight Klappich, Simon Tunstall, Rishabh Narang, 25 June 2024. Gartner, Cool Vendors in Logistics Technology, Dwight Klappich, Simon Tunstall, Brock Johns, et al., 30 August 2023

Gartner, Hype Cycle, and COOL VENDORS are registered trademarks of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

Atlanta, GA (March 11, 2024)

At the opening day of Modex 2024, Vimaan has announced the launch of the all-new PalletSCAN 360, a revolutionary machine learning and computer vison platform that improves the speed and quality of incoming and outgoing pallet scans. Available for live demonstrations at Booth A13227, PalletSCAN 360 is an automated, multi-sided scanning platform that increases warehouse labor productivity, improves quality, and decreases costs from chargebacks and reverse logistics.

The PalletSCAN 360 system includes a panel of LED lights which provides consistent illumination, along with high-definition cameras that deliver high-quality image capture. The panel is paired with an industrial strength turntable that rotates pallets as the system scans and documents cases on pallets. Once a pallet is placed on the turntable, PalletSCAN 360 activates and scans the entire pallet in as little as 15 seconds. Utilizing Vimaan’s industry leading computer vision technology, PalletSCAN instantly extracts and validates the full range of pallet attributes like barcodes, label text, images, dimensions, contours, item quantities, and quality metrics including package damage and discoloring.

“All the contents of a pallet are analyzed and reconciled with warehouse manifests. Cases that are missing or do not belong on a pallet are highlighted, as are cases with obscured, unreadable or missing labels. Along with validating the contents of each pallet, PalletSCAN 360 also counts the number of cases and alerts customers if quantities are off…all in a matter of seconds,” said Chahal Neema, Head of Product for Vimaan. “Each pallet is also stored in ultra-high digital resolution for archival purposes. Our customers can zoom in on individual cases, allowing them to read even the tiniest of label text and numbers. This capability is invaluable for claims processing as well as for analytics purposes.”

PalletSCAN 360 allows warehouses to retire outdated pallet auditing solutions like handheld barcode readers and limited use scan tunnels. “Fast and efficient data capture is just the start of the value we provide to our customers,” said KG Ganapathi, CEO and Founder of Vimaan. ”PalletSCAN’s analysis of pallet contents helps identify mistakes in near real-time before goods enter the warehouse or are shipped to customers. Along with scanning faster than manual processes, PalletSCAN 360 also detects errors before they become costly setbacks.”

The evolution of Vimaan’s pallet scanning capabilities is a direct result of deploying solutions for Fortune 50 Global Retailers, including for several distribution centers. PalletSCAN 360 is part of the family of PalletSCAN products, which additionally enable Auto Receiving, Drive-Through Dimensioning and Pallet Shipment Verification. Like StorTRACK and other Vimaan solutions, PalletSCAN 360 utilizes sophisticated computer vision algorithms, machine learning, a WMS integration layer and an intuitive easy to use web application, ViewDECK, that is accessible by inventory management personnel from anywhere. Vimaan’s entire product portfolio is engineered to support easy integration with existing workflows and deliver an unparalleled level of inventory tracking and validation within the four walls of the warehouse. “We look forward to unveiling PalleSCAN 360 at this year’s Modex and encourage anyone that wants to improve upon pallet content verification to stop by and even bring your own labels!” added Neema.

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

San Jose, CA (February 15, 2024)

Vimaan, the industry leading provider of computer vision, machine learning and AI solutions for supply chain inventory visibility today announced PalletSCAN 3D – an all-new automated pallet dimensioning solution for Distribution Center (DC) operators and freight carriers. Unlike other pallet dimensioning systems on the market, PalletSCAN 3D enables precise capture of pallet dimensions, weight and images – all with a simple “pick up and drive through” workflow.

PalletSCAN 3D is an extremely intuitive solution. The forklift operator picks up the pallet during normal processing, and simply drives through a “gate” that is placed inside the warehouse. It can support entry from either direction through the gate, as well as forward and reverse motion of the forklift. PalletSCAN 3D handles pallets from 1’ to 10’ in dimensions and generates results within seconds of passing through the gate. In addition to dimensions, the system can determine irregularities or safety hazards, such as skewed placement on the pallet, overhang or leaning stacks. The system also archives and provides searchable, photographic evidence of each pallet from multiple angles.

“Shippers, carriers and LTLs have long recognized the importance of accurately measuring pallet dimensions and weight because it directly impacts trailer loading efficiency, pricing, and regulatory compliance,” said KG Ganapathi, Founder & CEO at Vimaan. “But until now, all pallet dimensioning solutions have required a “stop and drop” workflow, which adds significant space overhead, labor and cost to the process. PalletSCAN 3D can dimension and weigh every pallet without any change to existing workflows, improve safety compliance, and ease claims processing.”

PalletSCAN 3D builds upon a suite of existing products that are based on Vimaan’s Machine Learning and Computer Vision technology platform. “It is uniquely challenging to distinguish the pallet from the forklift and dimension it accurately within a few seconds while the forklift is in motion – especially under a wide range of conditions including travel direction, forklift types, pallet shapes, driver speed, floor variations and lighting,” said Ganapathi. “Vimaan has deployed its unique platform of sensors and computer vision to solve this problem and demonstrated it to be accurate and effective at full operational scale.”

Vimaan already has multiple PalletSCAN 3D systems in operation at various DCs and cross-docks with large freight operators around the country. “All our customers for this product expressed the need to dimension pallets and inspect them for safety compliance without slowing down their operations,” continued Ganapathi. “This is essential to ensuring that they are effectively using freight space in outgoing trucks, and also maintaining safety standards. Every cubic inch of space counts and impacts their shipping costs. By using the drive-through workflow, dimensioning time per pallet is reduced from 2 minutes per pallet to less than 10 seconds per pallet.”

“Until now, all pallet dimensioning solutions have required a stop and drop workflow…PalletSCAN 3D can dimension and weigh every pallet without any change to existing workflows.”

— KG Ganapathi, Vimaan Founder & CEO

All Vimaan solutions are engineered to support easy integration with existing workflows. Like StorTRACK and other Vimaan solutions, PalletSCAN 3D includes ViewDECK, an intuitive web application to view results, search for historical data and images, and provide analytics and actionable intelligence to improve operations. For more information on PalletSCAN 3D visit: https://vimaan.ai/palletscan3d-pallet-dimensioner/

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

San Jose, CA (October 17, 2023)

Vimaan, the industry leading provider of computer vision solutions for warehouse inventory tracking and visibility, today announced that it has been named a Gartner Cool Vendor for Logistics Technology . This announcement follows a rapid time of growth for Vimaan in which the company has deployed AI-enabled warehouse tracking technology to some of the most well-known 3PLs, brands and retailers in the world. By deploying Vimaan technologies, these companies have been successful in streamlining their labor requirements and boosting their overall inventory accuracy levels. “Gartner provides research and advisory services to companies looking to leverage technology to solve real-world challenges,” said KG Ganapathi, Founder and CEO of Vimaan. “For us, this is a real acknowledgement and tremendous validation that we are delivering real value to the logistics and supply chain industries.”

The report states that “logistics organizations remain under pressure to control costs while dealing with unprecedented labor challenges.”

As one of the areas with the highest labor attrition rates, warehouses are being asked to reduce their dependencies on expensive and difficult to source workers. Vimaan computer vision solutions are being used to supplant hard to find labor across the warehouse including at the dock doors, storage racks and packing stations. “Scanning and tracking warehouse inventory with labor is very time consuming and expensive,” Ganapathi states. “As a result, inventory accuracy suffers and downstream processes are impacted; inventory gets lost, picking productivity suffers and costly chargebacks become a regular occurrence. Regardless of the WMS a warehouse uses, if the process for collecting data is inconsistent and unreliable than your data will reflect that.”

Vimaan captures inventory across several critical inventory workflows including receiving and shipping. DockTRACK Pallet allows warehouses to quickly scan all 5 sides of a pallet, count cases, dimension and even inspect for damages. Vimaan also provides DockTRACK Parcel, a comparable solution for incoming and outgoing packages. StorTRACK is a new solution launched by Vimaan earlier this year, has become enormously popular with customers for its ability to facilitate and automate cycle count activities. All Vimaan solutions interface with an intuitive WMS integration layer, ViewDECK, a web-based application that provides actionable insights and is accessible by inventory management personnel.

“For us, this is a real acknowledgement and tremendous validation that we are delivering real value to the logistics and supply chain industries.”

— KG Ganapathi, Vimaan Founder & CEO

Gartner, Cool Vendors in Logistics Technology, Dwight Klappich, Simon Tunstall, Brock Johns, et al., 30 August 2023

GARTNER and COOL VENDORS are registered trademarks of Gartner, Inc. and/or its affiliates in the U.S. and internationally and is used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

San Jose, CA (May 10, 2023)

Vimaan today announces the all new StorTRACK, the next generation in cycle counting technology that addresses the ongoing challenge of warehouse inventory accuracy. StorTRACK conducts automated scanning of warehouse shelves and uses advanced machine learning to read labels, count inventory, reconcile against a WMS, and generate a visual and digital reconstruction of the warehouse, thus enabling 100% inventory accuracy.

Vimaan was one of the first companies to introduce and scale indoor drones as a means of capturing images of warehouse inventory. However, after several years of scanning millions of items across Fortune 500 owned warehouses, Vimaan is raising the bar with the game changing StorTRACK platform – a safer, more efficient and more cost-effective solution that retains all the advantages of computer vision for inventory tracking.

“We started with the goal of being a 100% autonomous drone-based machine learning solution to enable cycle counting. However, after years of operational experience, our customers and we now believe that warehouse environments are not a good fit for autonomous drones,” said KG Ganapathi, CEO and Founder of Vimaan. “Even the best managed warehouses have unattended loose material like shrink wrap, packaging tape, corrugate, or paper on their shelves and floors. These items can get sucked into the drone’s rotors and cause catastrophic failure and potentially damage warehouse assets. As a result, frequent and thorough floor and shelf inspections are essential for safe drone operations. These in turn require labor, which dilutes the notion of full autonomy.”

StorTRACK replaces the drone with a stand-alone hardware module that is lifted and maneuvered by any MHE in the warehouse, including forklifts and order-pickers. The unit includes multiple smart cameras and integrated lighting, enabling a field of view 4X larger than a drone, which allows for more efficient shelf scanning. The system also includes localization and navigation capabilities and a built-in tablet, which provides intuitive real time guidance to the MHE operator on exactly how to conduct the cycle count. The unit’s battery has a 24X longer charge than a drone, allowing for much larger coverage of the warehouse in a single mission.

To enable a cycle count, an operator simply picks up the unit with the MHE and drives to the appropriate aisle location (with the guidance of the tablet display) to start the scanning mission. The system is then raised by the MHE forks, and automatically begins scanning inventory from the floor to the highest storage bay (and every shelf in between). This process is repeated along each aisle. The data is viewable on ViewDECK, Vimaan’s proprietary web application, and can also be integrated with major WMS providers –giving warehouse managers search and discrepancy reports as well as other actionable inventory insights.

StorTRACK has other advantages over a drone besides safety and scan efficiency. It is fully compatible with AGVs or autonomous forklifts, thus providing a “future-proof” path to truly safe and scalable 100% autonomous cycle counting. It enables on demand cycle counting and rapid scans of an entire warehouse which are often needed for quarterly or annual physical audits.

StorTRACK is also more cost effective than the drone. “StorTRACK provides a faster ROI for our customers,“ added Ganapathi. “It is less expensive than any drone-based solution on the market today, and we are in the process of converting all our drone-based customers to the new StorTRACK platform.”

Vimaan solutions are engineered to support easy integration with existing workflows. Like DockTRACK and other Vimaan solutions, StorTRACK leverages sophisticated computer vision algorithms, a WMS integration layer, and an intuitive, easy to use app, ViewDECK, that is accessible by inventory management personnel. Together, Vimaan’s product portfolio delivers an unparalleled level of inventory tracking and validation within the four walls of the warehouse.

.

This all-inclusive automation resource kit includes:

– Cycle Count Automation Demo Videos

– Real-world case study results

– Comprehensive automation guide

– Technology benchmark videos

– Product data sheets and specifications

– Sarbanes-Oxley compliancy technical note

– And more!

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

Allen, Texas (July 27, 2022)

PFS, a premier eCommerce order fulfillment provider and business unit of PFSweb, Inc. (NASDAQ: PFSW), today announced a partnership with Vimaan, a technology provider delivering computer vision-enabled solutions for warehouse inventory tracking, control and management. For over 20 years, PFS has been an eCommerce leader behind premier brands in health & beauty, fashion & apparel, jewelry, and consumer packaged goods.

Initially, PFS is integrating the first-of-its-kind self-flying warehouse drones to automate inventory tracking activities within one of PFS’s Memphis-based fulfillment operation that stores and picks, packs, and ships inventory for premier brands. Scanning inventory from the ground to the ceiling, the robots capture up to 1,500 areas and deliver highly accurate inventory status details to the PFS Warehouse Management System (WMS). The implementation of this solution will improve the accuracy and traceability of client product inventory across PFS’ fulfillment centers.

“With the rise in demand for multi-node fulfillment operations, it’s more critical than ever to track inventory more efficiently across our facilities,” noted Jon Gardner, Senior Vice President of Fulfillment Operations at PFS. “Vimaan’s technology allows us to implement real-time tracking against our WMS more accurately, efficiently and safely. It also enables PFS to deploy immediate investigation and adjustments to improve accuracy and responsiveness for our clients. The implementation of this technology means another step forward for PFS’ efforts to drive innovation across our facilities in support of our clients’ eCommerce operations.”

“We believe near real-time 100% inventory accuracy and visibility across the entire warehouse is attainable. PFS is not only ahead of the curve by being one of the first in the industry to utilize this groundbreaking technology, but they’re also a valuable partner to us as we continue to innovate our technology and solutions,” noted S.K. (“KG”) Ganapathi, Vimaan Founder and CEO. “We expect PFS to gain significant efficiencies during the cycle count, receiving and packing audit processes, resulting in the same significant savings other clients have seen using this technology.”

The technology is being initially deployed at a single location within PFS’ Memphis-based fulfillment campus with current plans to roll out to remaining global fulfillment centers through 2023.

“The deployment of this technology is another key step in our planned innovation roadmap,” commented Zach Thomann, COO and President of PFS. “We are continuously looking at additional methods to produce more efficient eCommerce fulfillment operations, such as autonomous mobile robotics, goods-to-person systems and advanced scanning technology. We have opportunities to improve our inbound receiving, put-away, quality inspection and shipping processes by deploying these types of solutions and will continue to explore additional capabilities that will benefit our clients. Vimaan has been a great partner to help us achieve these objectives with technology and consultation.”

About PFS

PFS, the business unit of PFSweb, Inc. (NASDAQ: PFSW) is a premier eCommerce order fulfillment provider. We facilitate each operational step of an eCommerce order in support of DTC and B2B retail brands and specialize in health & beauty, fashion & apparel, jewelry, and consumer packaged goods. Our scalable solutions support customized pick/pack/ship services that deliver on brand ethos with each order. A proven order management platform, as well as high-touch customer care, reinforce our operation. With 20+ years as an industry leader, PFS is the BPO of choice for brand-centric companies and household brand names, such as L’Oréal USA, Champion, Pandora, Shiseido Americas, Kendra Scott, the United States Mint, and many more. The Company is headquartered in Allen, TX with additional locations around the globe. For more information, visit www.pfscommerce.com or ir.pfsweb.com for investor information.

.

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

Santa Clara , CA (June 23, 2022)

Vimaan today announces PackVIEW, a one-of-a-kind, patent pending fulfillment solution which leverages the power of computer vision to provide an unparalleled level of order fulfillment accuracy, loss prevention and quality control for warehouses and fulfillment centers. PackVIEW automatically records and validates items during the order packing process, helping support improved operator efficiency, order quality and customer satisfaction.

The ongoing surge in eCommerce has placed a strain on already taxed order fulfillment solutions. Most warehouses and fulfillment centers still require manual entry and validation during order assembly, which slows processes down and introduces several points of failure. Additionally, increases in online orders have contributed to fulfillment inaccuracies, lower quality output and customer disputes. Without the use of a digital archive, warehouses lack evidence that orders were satisfactorily assembled and fulfilled as required.

“We hear from companies both big and small that there is a direct correlation between order volume and increasing quality challenges,” stated Philip Archambault CRO and VP of Sales for Vimaan. “Warehouses and fulfillment centers have needed a quality assurance solution for some time now that both validates items prior to packing and audits the physical fulfillment activity as it is happening. That is exactly why we have engineered PackVIEW.”

In production at multiple customer sites already, PackVIEW is platform agnostic and performs audits against order manifests from WMS, ERP and other inventory management systems or even extracts data directly from a physical pick order.

Order packers use the PackVIEW interface to validate SKUs and volumes from manifests and are alerted in real time when orders are inaccurate and/or incomplete. “This added level of quality assurance ensures that packed orders are 100% correct before being shipped to customers. Additionally, PackVIEW provides a digital and photographic record of all fulfilled orders to resolve customer disputes easily and efficiently,” added Archambault. “We believe this is a highly differentiated solution because we are optimizing the entire workflow and recording evidence of every order fulfilled. We are thrilled to see the quantifiable benefits our customers are already receiving from PackVIEW.”

Engineered to support easy integration on top of existing workflows, all Vimaan solutions require little to no infrastructure changes or training for the warehouse workforce. Like PickTRACK, StorTRACK and DockTRACK, Vimaan’s previously announced solutions for inventory tracking, PackVIEW leverages Vimaan’s powerful platform of sensors, cameras, sophisticated computer vision algorithms, a WMS integration layer, and an intuitive, easy to use app, ViewDeck, that is accessible by inventory management personnel. Together, Vimaan’s product portfolio delivers an unparalleled level of inventory tracking and validation within the four walls of the warehouse

.

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

Santa Clara , CA (May 2, 2022)

Vimaan today announces PickTRACK, a one-of-a-kind, patent pending computer vision solution enabling an unparalleled level of inventory accuracy and visibility in warehouses. PickTRACK automatically validates pick and put actions performed from Material Handling Equipment (MHE) without changes to existing infrastructure or workflows.

Today, most inventory “pick” and “put” processes in warehouses require warehouse associates to use handheld scanners to manually scan item and location barcodes, in addition to entering inventory quantities. This process not only imposes an overhead on labor productivity; it also invariably introduces errors due to missed or incorrect barcode scans, wrong quantities entered, or picks and puts from wrong locations – which in turn lead to inaccurate WMS inventory records. PickTRACK is designed to address these specific problems through a suite of sensors and cameras that fit on to existing MHE (such as forklifts or order pickers) that observe and track inventory events and locations in near real time. With these capabilities, PickTRACK offers several distinct advantages:

1. PickTRACK pulls “picklists” or “put” tasks directly from the WMS and validates MHE activity against these task lists. It highlights any discrepancies (item LPNs, quantities or locations) in near-real time, thus ensuring put and pick accuracy against the WMS.

2. While tracking and ensuring pick and put task accuracy, PickTRACK simultaneously allows for automatic incrementing and decrementing of inventory at locations, enabling continuous cycle counting and the highest possible inventory accuracy for warehouse managers. This capability improves worker productivity by both eliminating manual barcode scans as well as reducing the time searching for missing items.

3. PickTRACK tracks precise dynamic MHE location in real time through advanced localization capabilities enabled by the sensor suite. This allows warehouse managers to generate analytics and improve metrics related to MHE usage, efficiency and productivity.

4. PickTRACK maintains searchable photographic archives of the picks and puts, allowing rapid research into the source of discrepancies against WMS directed activities. This also enables easier claims processing as well as more effective training of associates.

The effectiveness and value of PickTRACK has already been validated by Vimaan customers currently in production with the solution. “Our early PickTRACK customers have reported significant improvements in inventory accuracy,” stated Shane LaChappelle, Head of Product Management at Vimaan. “These customers have also reported corresponding reductions in time spent searching for inventory, as well as a dramatic reduction in customer claims and chargebacks related to inaccurate order fulfilment.”

“We provided a sneak peak of PickTRACK a few weeks ago at MODEX, and the response was overwhelmingly positive,” continued LaChappelle. “There was an abundance of solutions at the show that featured improved ways of handling inventory, but no one is tackling the challenges of inventory accuracy and visibility. As autonomous solutions such as AMRs and AGVs become more prevalent in warehouses, it will become important for warehouse operators to have visibility into and validation of the inventory moves being conducted by these robots. PickTRACK will be a perfect add-on to these robots for such applications.”

Like StorTRACK and DockTRACK, Vimaan’s previously announced solutions for inventory tracking, PickTRACK leverages Vimaan’s powerful platform of sensors, cameras, sophisticated computer vision algorithms, a WMS integration layer, and an intuitive, easy to use app, ViewDeck, that is accessible by inventory management personnel. All Vimaan current and future solutions are designed to support easy integration into existing workflows, with little to no infrastructure changes or training required for the warehouse workforce. Together, Vimaan’s product portfolio delivers an unparalleled level of inventory tracking and validation within the four walls of the warehouse.

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing

Santa Clara , CA (April 26, 2022)

After spending years in development and working with some of the largest 3PLs and brands to hone its technology and solutions, Vimaan has released two new transformative products, StorTRACK and DockTRACK, both currently in production at multiple customer sites. StorTRACK, a fully automated solution for cycle counting, enables improved warehouse inventory accuracy and increased frequency of cycle counting at greatly lower costs. DockTRACK automates and increases the accuracy, visibility, and quality for receiving and shipping workflows. Both Vimaan products also detect damage and other inventory anomalies before items enter or leave a customer’s facilities.

“We were not actively soliciting an investment when approached, but when one of the largest and most innovative supply chain companies in the world recognizes the value in our solutions for the entire supply chain inventory management industry, it is easy to get excited,” stated S.K. (“KG”) Ganapathi, Vimaan’s Founder and CEO. Vimaan will use the funds to accelerate the addition of leading Fortune 500 companies to its customer base. “This investment will enhance our roster of blue-chip investors and customers, and further help build Vimaan’s reputation as a must have inventory management solution for all warehouses,” added Ganapathi.

“The purpose of the Amazon Industrial Innovation Fund is to support emerging technologies through direct investments, designed to spur invention and solve for the world’s toughest challenges across customer fulfillment operations, logistics, and supply chain solutions,” said Katherine Chen, Head of the Amazon Industrial Innovation Fund. “We are delighted to be making this investment in Vimaan. We believe their underlying computer vision technology platform is extremely innovative, differentiated, and highly relevant to solving everyday inventory management problems faced across a wide range of facilities.”

Headquartered in Silicon Valley, Vimaan’s team comprises computer vision and hardware technologists and warehousing domain experts with a rich and successful history in technology startups. Vimaan’s primary mission is to deliver computer vision and machine learning solutions to solve long-standing inventory visibility, accuracy and quality challenges experienced in the supply chain.

Media Contact: Craig Dowley VP, Marketing