Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

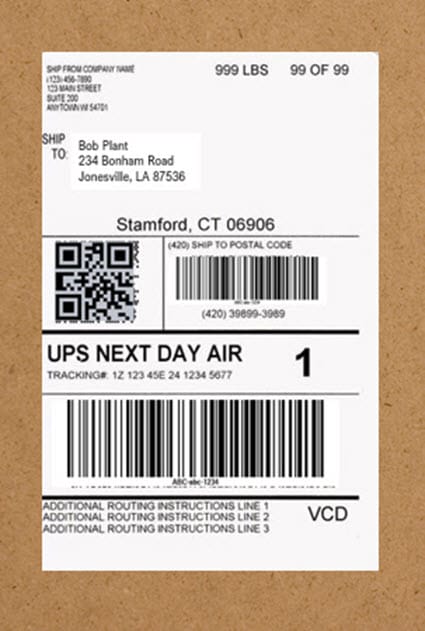

In warehouse operations, scanning UPS shipping labels plays a critical role in enabling accurate tracking, efficient routing, and timely delivery. Each UPS label contains essential data—tracking numbers, service levels, ship-to addresses, and barcodes—that are integral to ensuring packages are received, processed, and shipped correctly. Inefficiencies in UPS label scanning can lead to delayed shipments, misrouted packages, inaccurate inventory counts, and increased labor costs. This is why leading brands and 3PLs have adopted Vimaan warehouse computer vision solutions to ensure UPS label data is captured accurately and consistently at every touchpoint.

Despite its importance, scanning UPS labels reliably can be difficult in real-world warehouse environments. Several operational challenges can disrupt this seemingly straightforward process:

Traditional warehouse barcode reading solutions such as handheld scanners are slow and unreliable in addressing the multitude of challenges organization experiencing when trying to effectively capture and scan UPS shipping labels. Vimaan AI-enabled computer vision addresses these challenges with its advanced image capture AI-enabled computer vision solutions designed to automate label scanning and data capture with superior accuracy, consistency, and speed. Our systems deliver enterprise-grade performance across diverse operational environments.

Hands-Free, Automated Scanning – Vimaan systems are designed to capture UPS label data automatically—without requiring manual scanning. Whether mounted at receiving docks, added to conveyors, or integrated into packing stations, our computer vision systems continuously scan and interpret UPS labels in real time.

High Accuracy in Suboptimal Conditions – Powered by advanced AI and optical character recognition (OCR), Vimaan accurately reads UPS labels that are wrinkled, partially obscured, damaged, or affixed in nonstandard positions. The system recognizes multiple carrier formats and reliably extracts tracking and routing data.

Real-Time Data Synchronization – Vimaan integrates seamlessly with WMS, TMS, and ERP platforms, enabling real-time synchronization of scanned data. This ensures accurate updates to inventory systems, immediate identification of exceptions, and improved process control.

Automated Exception Handling – Label mismatches, unreadable barcodes, or improperly routed shipments are flagged automatically. These alerts allow warehouse teams to proactively address issues before they escalate, reducing operational disruptions and improving customer service metrics.

Improved Efficiency and Lower Labor Costs – By reducing the dependency on labor for manual UPS label scanning, Vimaan increases throughput while minimizing labor-related variability. Organizations benefit from consistent scanning performance across all shifts and a measurable reduction in labor costs.

Vimaan provides the most complete shipping label scanning and reporting solution for the warehouse. The AI-enabled computer vision platform is deployed across all Vimaan systems to provide accurate and precise UPS label scanning when you need it the most, this includes:

Package & Parcel Receiving – using the Vimaan ParcelSCAN labels on incoming UPS containers including envelopes, boxes, polybags and more are scanned on existing conveyors moving up to 3 feet per second.

The highly configurable Vimaan systems can handle the widest array of containers with UPS labels (and other major shipper labels including FedEx) such as envelopes, small boxes, large containers, polybags, shipping tubes, pallets and more. No matter the shape or container form factor, Vimaan systems scan UPS labels quickly and even provides visual proof of each item in an image archive available for up to 90 days or more. Vimaan’s automated label scanning solutions are already driving measurable improvements in warehouses across North America.

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Fast scannin, tracking and validation of incoming and outgoing packages with ParcelSCAN

Step by step technical overview and cycle count demonstration of StorTRACK scanning pallets, cartons and eaches.

See firsthand how this diverse set of pallet scanning systems solve the most common and time intensive warehouse challenges including: