Warehouse Package Scanning

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Your browser is out of date, for the best web viewing experience visit Browse Happy to upgrade your browser today.

In most warehouses the outbound pallet shipping process remains highly manual and labor intensive. Prior to shipping, associates examine all visible pallet faces, packages and scan outgoing label barcodes. The pallet is also usually dimensioned, weighed and inspected for damage, which is also time consuming. This process can take 3-5 minutes (or longer) per pallet and occupies the time of both the clerk and MHE (Material Handling Equipment), in addition to taking up valuable space in the shipping docks. Major 3PLs and Brands have reduced the time, labor, and effort involved in shipping by deploying automated vision solutions from Vimaan.

Vimaan’s PalletSCAN solution completely automates, streamlines and digitizes the outbound pallet shipping process. This reduces labor and MHE requirements, reduces clutter and real estate usage at the shipping gate, and provides extensive searchable data that can be used for subsequent dispute resolution or analytics. Vimaan sensors automatically read pallet labels from all five visible sides of a pallet, inspect for damage and even measure package dimensions – all from simply driving or walking through an outbound “gate”.

Vimaan automates the outbound pallet shipping process using a combination of sensors, cameras and proprietary computer vision and machine learning technology. The solution comprises two components:

How Pallet Shipping Automation Works

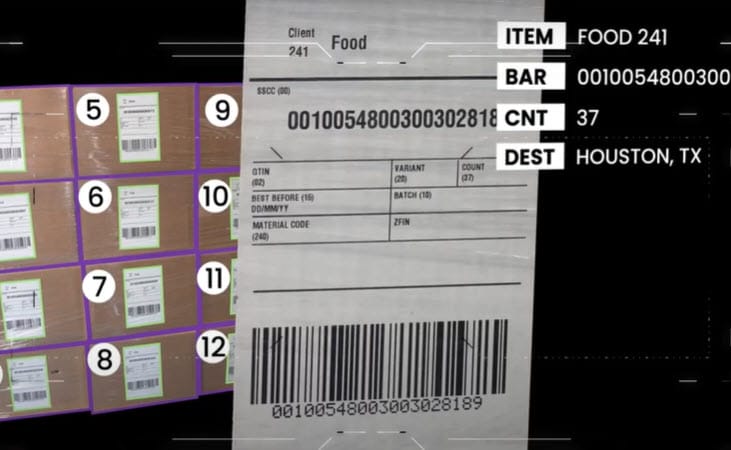

During the automated shipping process, Vimaan PickTRACK sensors automatically detect when drivers approach and pick up outgoing pallets. The front face of the pallet is scanned automatically, once the driver starts to drive through the PalletSCAN “gate” the sensors automatically detect the presence of the pallet and then proceeds to capture and read attached labels. Vimaan’s proprietary computer vision and machine learning software collates data collected from the sensors and cameras to extract label information, dimensions, and examines for damage, and other anomalies.

If there are errors in the shipment, the driver is notified through a beacon – which allows him to fix an error prior to loading the pallet in the outbound truck. Images of the pallet and the labels are captured for every outgoing pallet,and can be easily searched and retrieved through Vimaan’s easy to use ViewDeck application.

It is important to note that NO change to the normal shipping workflow is required. If shipping is done on an MHE, the driver simply picks up the pallet and drives through the gate. If shipping is done with electronic pallet jacks, the associate simply picks up the pallet and walks through the gate.

Pallet Shipping Capabilities and Metrics

Other automated pallet shipping systems only scan barcodes, while Vimaan reads the entire label:

This enables significant cost savings through lower labor requirements, while making the process of pallet shipping faster with higher quality results. Using Vimaan’s solutions, process times can improve from ONE pallet every THREE minutes (or longer) to THREE pallets (or more) every minute! This includes the automation of 5-sided pallet capture, 1D/2D barcode reading, label text reading, damage detection, dimensioning, WMS (Warehouse Management System) validation, and image capture and archiving.

Vimaan sensors and computer vision equipped on PalletSCAN and added to material handling equipment quickly and efficiently scan all 5 sides of inbound and outbound pallets up to 3X faster than traditional manual methods. Learn More

See firsthand how this diverse set of pallet scanning systems solve the most common and time intensive warehouse challenges including:

Fast scanning and validation of incoming and outgoing packages with ParcelSCAN

Warehouses are capturing all 4 sides of pallets faster than ever before with PalletSCAN 360.

Distributors reliably scan all outgoing cases in seconds ensuring customer orders are correct before shipping

Fast Ti-Hi pallet cases counting and SKU verification with instant validation and reporting

Capture all four sides of a pallet in under 15 seconds, inspects for damaged and validates instantly

Scans, Tracks and INSPECTS High Volume Packages during inbound receiving and outbound shipping.